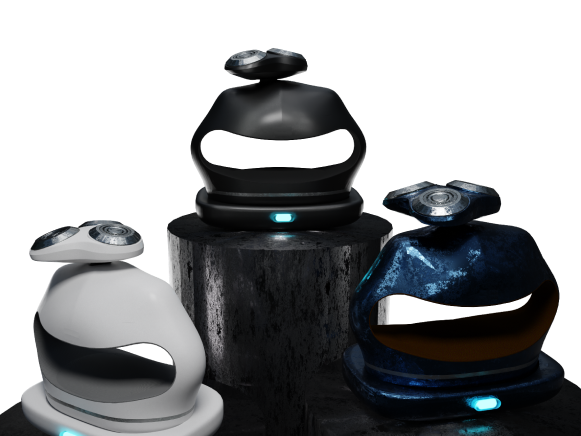

Concept Breakdown

Pepsi cans were identified as a major sustainability issue, and this pouch-based system was my alternative design. The pouch offers the following improvements:

+ 100% recycled packaging materials.

+ Can be poured, stored, or used on the go.

+ Reusable, lighter, and more space-efficient.

+ Lower material (and eventually production) than alternative packaging types.

+ 100% recyclable and 90% biodegradable (by weight).

+ No choking hazards – child-friendly format.

Data Analysis

When assessing the feasibility and scope of my new design, the following insights were drawn:

+ Advancements in barrier film technology makes it possible to hold carbonated drinks in pouches.

+ Paper pouches will be the lightest and most space-efficient form of packaging on offer.

+ Paper pouches would take 2-6 weeks to biodegrade, compared to plastic bottles at 15-20 years, and aluminum cans at 80-100 years.

+ The reusable and resealable design allows the pouches to combat the growing pressure that Pepsi faces to race toward a reusable beverage container.

The Problem

When interviewing for PepsiCo (before receiving a 6-month placement offer) I was given 1 week and the following brief, "Choose one of our UK brands… How would you help PepsiCo to meet our Pep+ sustainability goals for this brand if given £1,000,000"

Why Pepsi?

PepsiCo is a parent company with over 30 subsidiaries including conglomerates such as Lays, Gatorade, and Doritos. Despite this, I chose Pepsi for the following reasons:

+ Pepsi is amongst the 12 major brands accounting for 70 percent of packaging litter in the UK.

+ Pepsi is sold in 200 countries.

+ Pepsi is PepsiCo’s most influential brand product.

+ Reports say plastic from Coca-Cola, PepsiCo, Nestlé, and Unilever products could cover 83 football pitches every day.

+ Pepsi cans are 65% recycled material but should be at least 90% according to independent studies.

What Could Improve?

The next step of the process was to identify pain points that could be mitigated through a sustainable solution.

+ Current Pepsi cans are made from 35% raw materials.

+ Aluminium farming creates acid rain and oxygen-free zones in the ocean.

+ Bauxite mining contaminates local water supplies.

+ Glass formation requires enormous amounts of fossil-fuelled energy.

+ Glass production creates carbon dioxide.

+ Most of the energy is lost in glass recycling, making it inefficient.

+ Recycling still uses a lot of energy due to its high melting temperature.

+ Plastic bottles do not biodegrade.

+ Plastic packaging creates harmful microparticles.

+ Plastic cannot be endlessly recycled like aluminum or glass.

Advertisement

As a part of my pitch, I presented the following examples of how this product could be advertised. This included an example poster (left) and in-situ photoshops of what this might look like in common advertisement spaces.