The Focus

A mouthguard that makes it easier for boxers to breathe, speak, and compete fairly while in the ring, using metamaterials and embedded sensors.

Metamaterials

FLOAT has a lattice-based metamaterial structure for permeability leading to increased airflow, reduced volume, and thus an ability to drink and speak whilst wearing the mouthguard. With three separate layers, FLOAT maximises efficiency by putting protection where it's needed and maximising airflow where it's not.

+ Customisation and Design Flexibility

+ Energy Absorption and Dissipation

+ Lightweight and Comfort

+ Breathability and Hygiene

Intelligent Information Analytics

Float has a built-in smart microprocessor that can identify and analyse impacts to the athlete's head in real-time. This technology can help prevent serious injuries, and it can provide a more accurate assessment of an athlete's condition during a match. This intelligence helps keep boxers safe and referees informed. All data can be downloaded in real-time via a Bluetooth connection with the microprocessor.

+ Impact Recognition

+ Power Estimation

+ Emergency Medical Support

Molded Form

Once moulded, FLOAT looks similar to other mouthguards you may be familiar with. The one exception is that it retains all of its phenomenal mechanical properties, enabling you to perform at your best.

Molding FLOAT

1. Place in boiling water for 60 s.

2. Align with teeth and pinch shut with the jaw

3. Fold the flat FLOAT up towards your gums, ensuring you cover all of your teeth.

4. Massage the mouthguard until a comfortable and tight fit is formed.

5. Leave FLOAT in your mouth, taking routine sips of cold water if necessary.

What's in the Box?

1 x FLOAT Mouth Guard

1 x Electromagnetic Charging Dock

1 x Holding Case

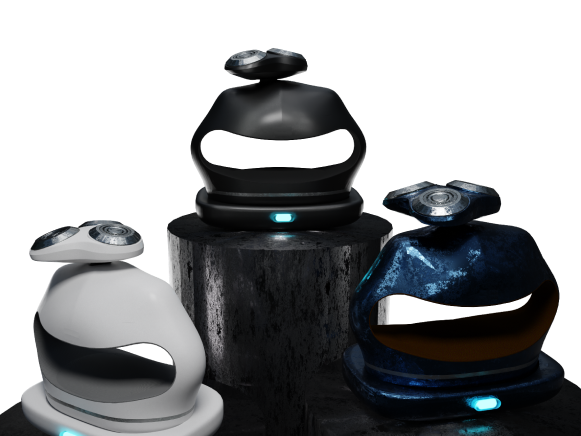

Colorways

Grey

Salcombe Mud - Light Blue - Moss Green - Lavender

Sand Dune Yellow - Violet - Raspberry

Technical Specifications

Power

Run time: 1000 minutes

Battery Type: Li-Ion

Charging: Wireless Charging Pad

Full charge: 80 minutes

Design Color

Grey

Salcombe Mud

Light Blue

Moss Green

Lavender

Sand Dune Yellow

Violet

Raspberry

Service

Replacement: Replace every 100 hours of use

2-year Warranty: Yes

Performance

Impact Recognition

Power Estimation

Emergency Medical Support

Waterproof

Cleaning

Fully washable using a toothbrush and toothpaste

Literature Review

A literature review of relevant topics demonstrated that mouthguards have the following roles and advantages:

+ Evenly dissipates forces

+ Reduces jaw movement

+ Lowers tooth impact

+ Decreases risk of jaw fractures

Additionally, the following insights were drawn about mouthguard design:

+ EVA mouthguards are more protective than Polyurethane ones

+ Most vulnerable teeth: cervical region of upper central incisors

+ Microchips shouldn't be placed here due to risk

+ Recommended chip placement: under the molars

Tribst, J.P.M., Dal Piva, A.M. de O., Borges, A.L.S. and Bottino, M.A. (2018). Simulation of mouthguard use in preventing dental injuries caused by different impacts in sports activities. Sport Sciences for Health, 15(1), pp.85–90. doi:https://doi.org/10.1007/s11332-018-0488-4.

Sketching Ideation

Morphological Analysis and eight-point design methods were the initial steps, providing a structured method of analysing multiple aspects of a proposed solution. These methods helped brainstorm the concept of a mouthguard.

Sketching ideation was conducted next, and users were consulted to select ideas to be considered and developed going forward.

Sketching ideation was conducted next, and users were consulted to select ideas to be considered and developed going forward.

Extended Ideation and Low Fidelity Prototyping

Those ideas that were explored were experimented with in CAD using a range of software and techniques, creating a strong mix between divergent and focused exploration and analysis.

CAD Modelling

Leveraging CAD enabled the creation of meticulous and adaptable design parameters tailored to diverse jaw structures and dental configurations.

Before investing in physical prototypes, the design was tested virtually, iterated on, and refined, ensuring its efficacy and user comfort.

Finite element analysis was also carried out in SolidWorks, determining reactions to real-world impacts.

High Fidelity Prototyping

Looks Like Prototype

A looks-like prototype was created to allow for a physical investigation of the size, shape, and aesthetic of the design.

Lattice Modelling

Lattice properties vary with size, structure, and solidarity. These features were investigated and the results were recorded.

Lattice Demonstration

Once lattice structures were finalized and allocated, they were prototyped in a scaled version of the mouthguard to enable a clear demonstration of the different layers within the design.

Exploded View

To demonstrate effectively the difference in lattice structures between layers, and within layers, an exploded perspective view was prototyped, for a visual representation used during presentations.

CMF Exploration

Once CAD and testing were concluded, and a design was finalized, colors, materials, and variants of these parameters were finalized. This produced the final CAD models shown below.

Awards

Nomination at the Design Intelligence Award from the China Academy of Art.