The Problem

ALS patients suffer from product neglect. In the UK the NHS provides limited support to those suffering from the condition, and other commercial appliances set you back the cost of the average family SUV. ZB Design has worked to provide a solution that is affordable to the masses, whilst still adhering to the functional needs of a patient.

The Solution

Project Comfort is a sustainably built, flat-packable, cost-effective solution to the question, "can I still be comfortable with ALS?". Through hundreds of user iterations and trials, Project Comfort has listened to ALS patients and attempted to create a solution that caters to all, for a fraction of the price of other brands.

The Thought Process

Comfort is a priority, cost is a necessity, and aesthetics is a requirement. ALS can present obstacles to patients, both through the presence of stigmatism over sitting in a wheelchair for what could be the first time and the financial burden that specialist equipment imposes.

Project Comfort uses everyday objects in an intelligent way to create a solution that caters to these issues, with a low-cost but stylish design never seen before in the wheelchair space.

Features

A wheelchair that you can feel comfortable in, both physically and mentally, helping you live on your terms without sacrificing comfort.

+ Adjustable: You can adjust many features of Project Comfort, including the legrests, footrests, headrest, and lumbar support.

+ Safety: Project Comfort has a fully detachable seatbelt system for use by those who want to be held into the chair.

+ Size: Project Comfort refuses to squash you into a small space. Breath easily, and live freely in this luxuriously large design, that will still fit through any standardized door frame.

+ Durability: Project Comfort is made with strong composite materials utilizing natural strengths, ensuring a long-lasting and efficient design.

Full Specifications

Adjustability

As ALS progresses, patients' needs change. Project Comfort is easily adjustable in terms of seating position, headrest, footrest, and other support elements.

Head Support

An adjustable and comfortable headrest. As neck muscles weaken, adequate head support becomes essential and Project Comfort takes this into full consideration.

Safety Features

Project Comfort has industrial-level brakes, anti-tip bars, and seat belts.

Ease of Transfer

Project Comfort facilitates easy transfer from and to the wheelchair.

Customizable Support

Project Comfort allows for additional cushioning or support to be added, particularly in areas prone to pressure sores or discomfort such as the back.

Maintenance

Easy maintenance due to the use of high-quality vinyl leather that wipes clean.

Durability

Project Comfort is made with strong composite materials utilizing natural strengths, ensuring a long-lasting and efficient design.

Size

Project Comfort refuses to squash you into a small space. Breath easily, and live freely in this luxuriously large design, that will still fit through any standardized door frame.

Aesthetics

Just because it's functional doesn't mean it can't be stylish. Project Comfort considers modern designs and customization options that allow users to express themselves.

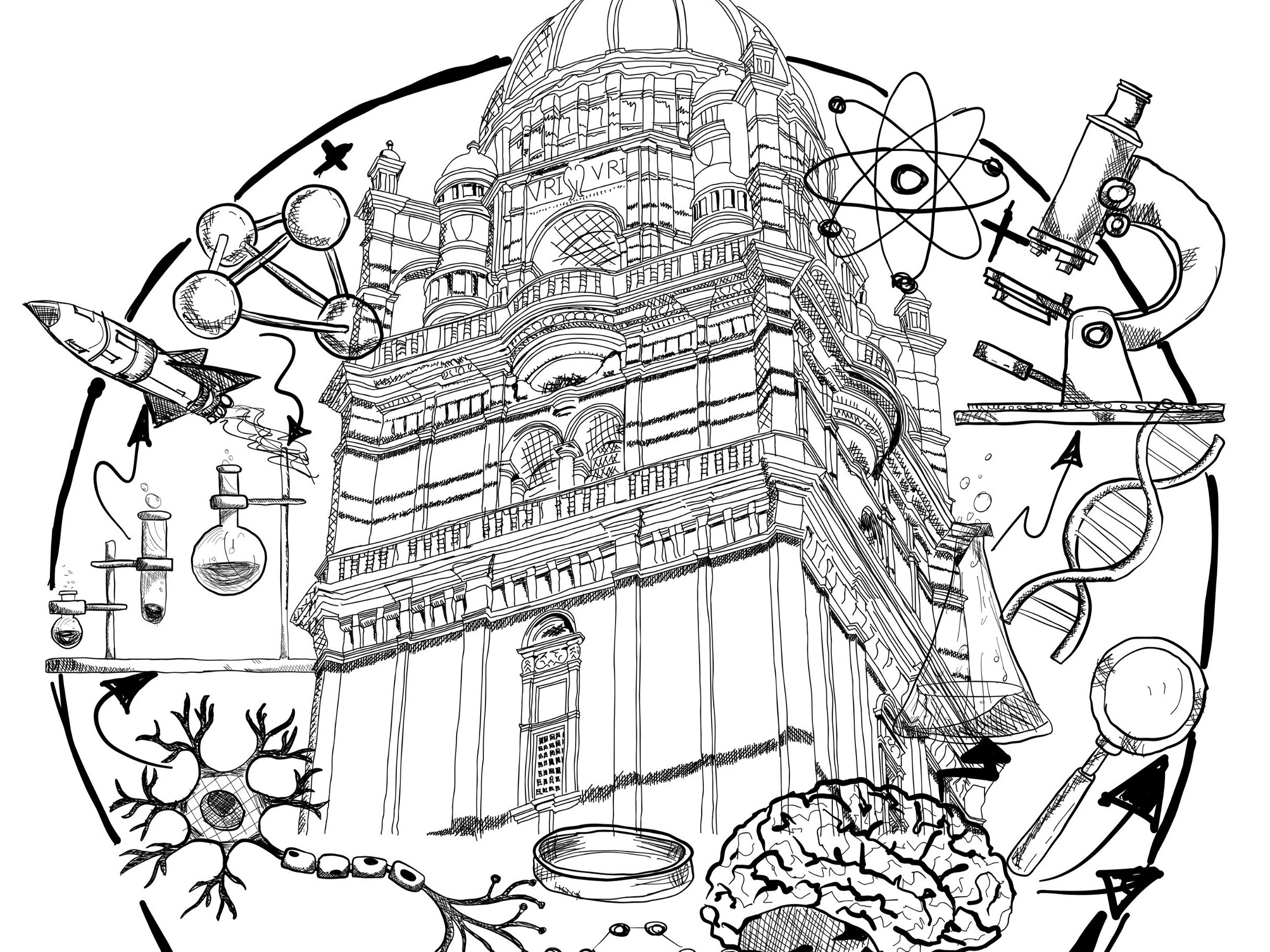

Ideation Techniques

Five approaches were explored to ideate wheelchair ideas and gather information on existing products. Primary and secondary research was conducted and mood boards, analogy, and metaphor design methods were used with sketching to come up with new ideas.

Sketching Ideation

Once wheelchair specifications were drawn up through user group ideation sessions, initial ideas were created that matched these profiles and could be examined further by users.

CAD Ideation Development

To further push the ability of these initial ideas to draw out user opinions CAD models were constructed in Fusion 360 and were used as supplementary materials when users were reviewing the designs.

Sketching Final Development

Once a final design was selected final iterations were discussed, an initial draft of what this could look like was sketched up.

Sketching Final Iterations

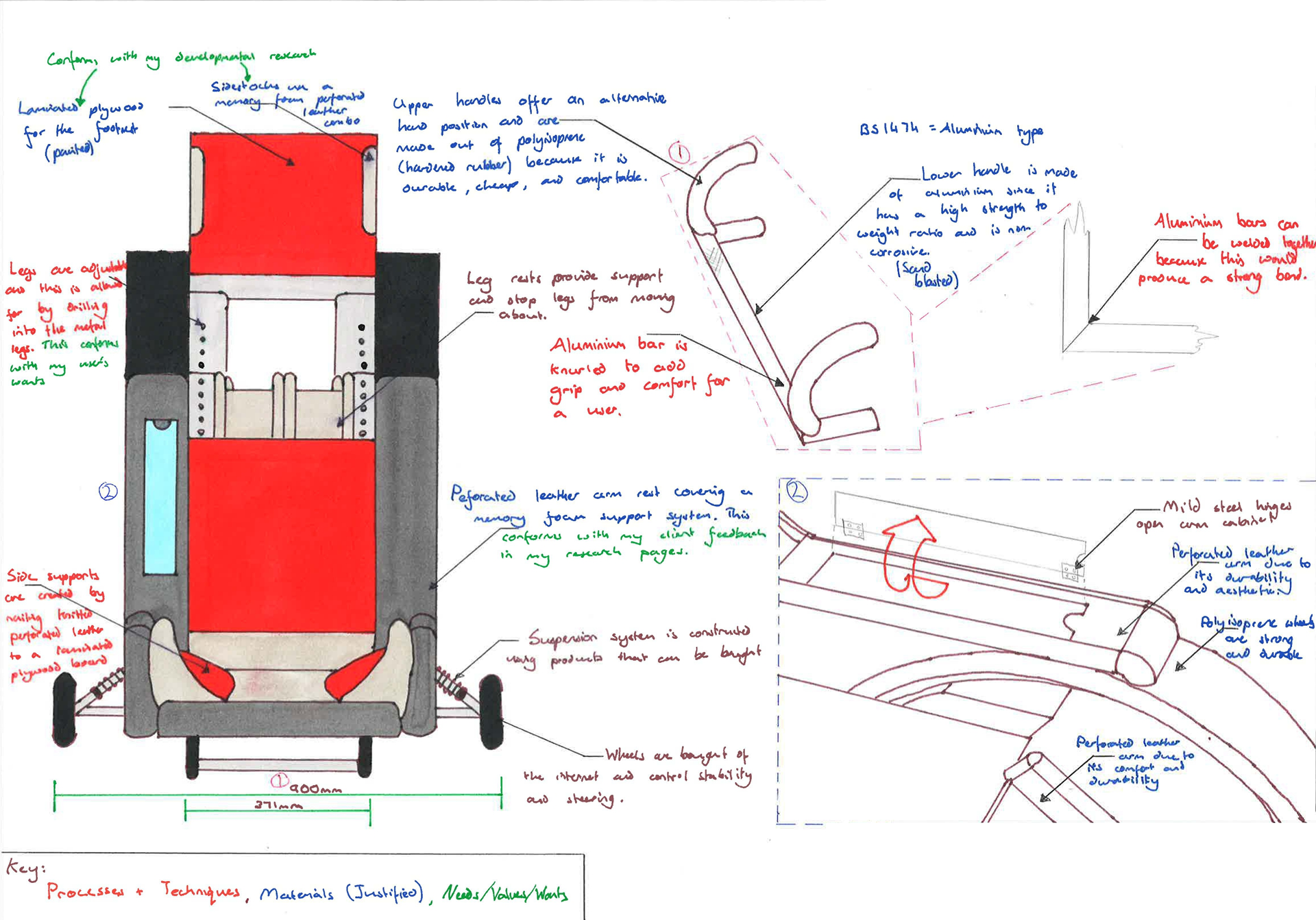

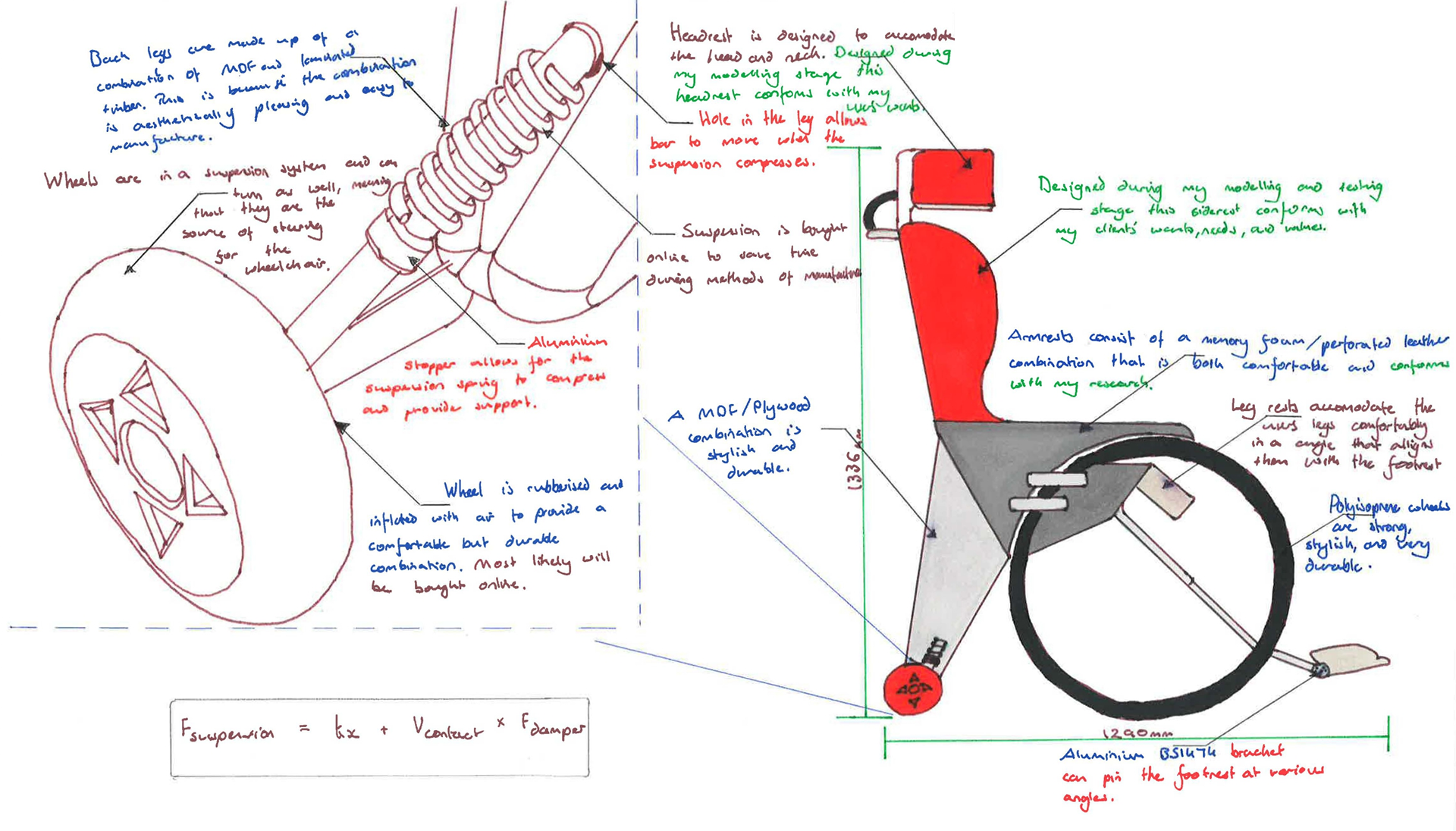

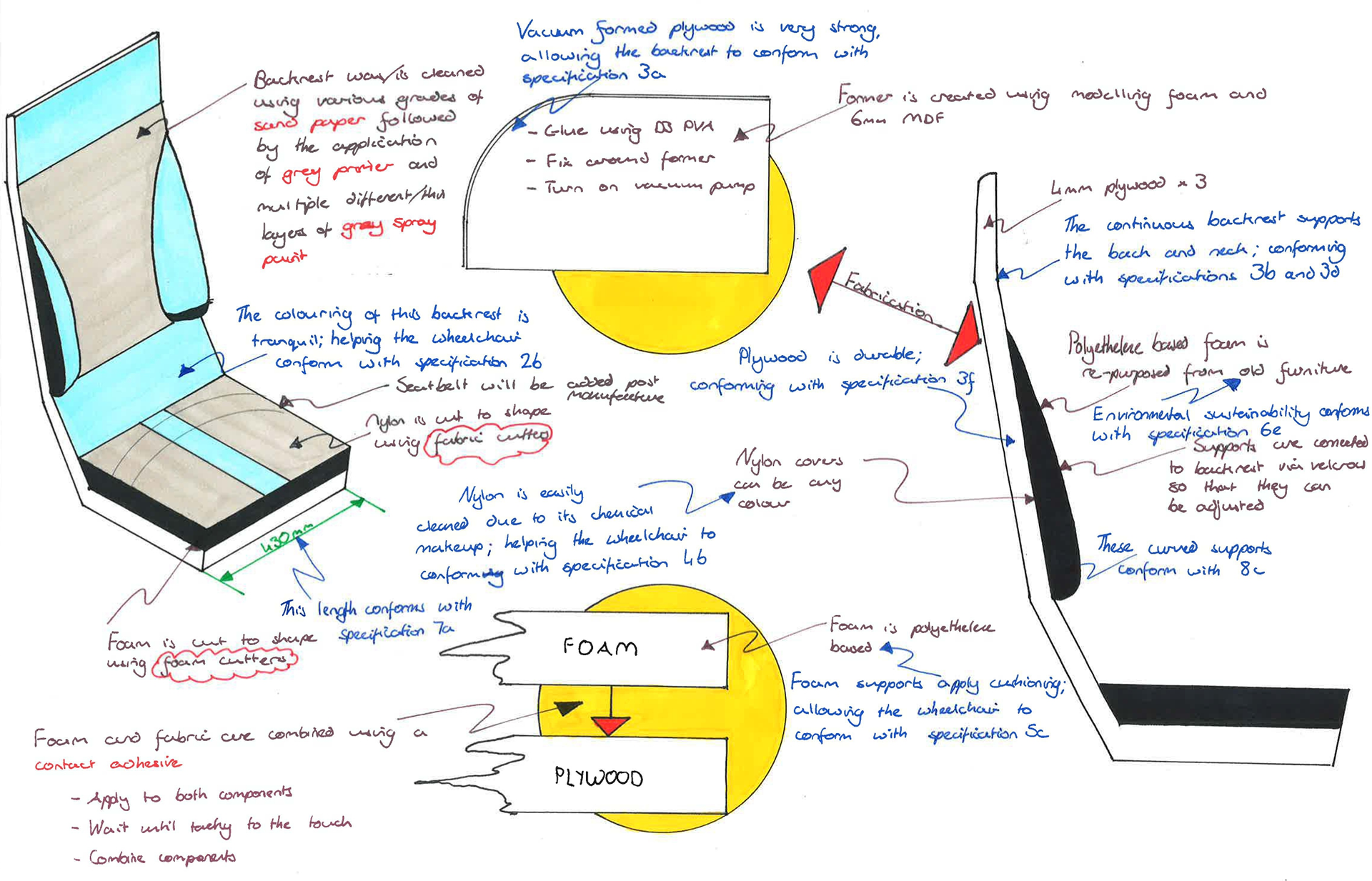

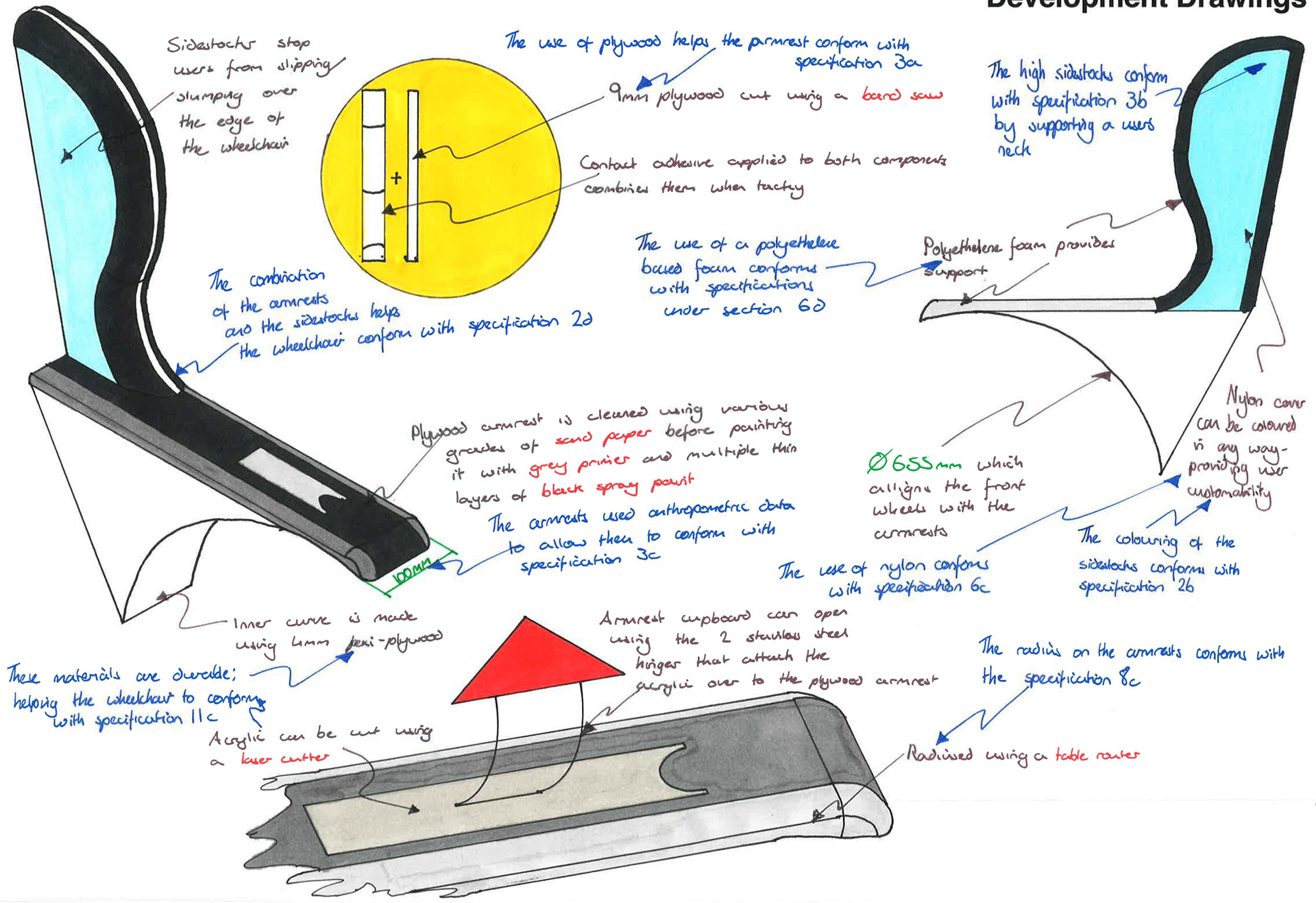

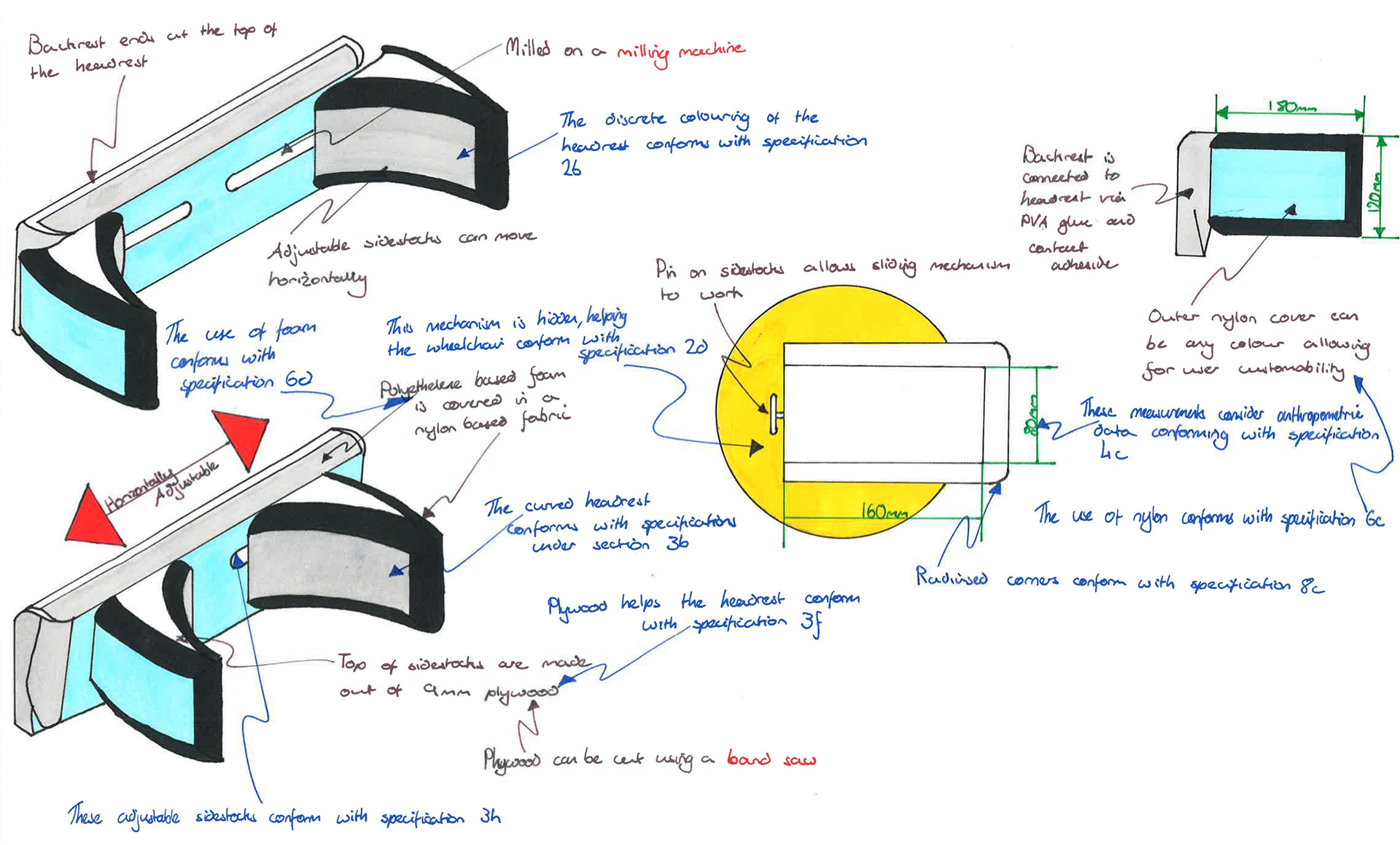

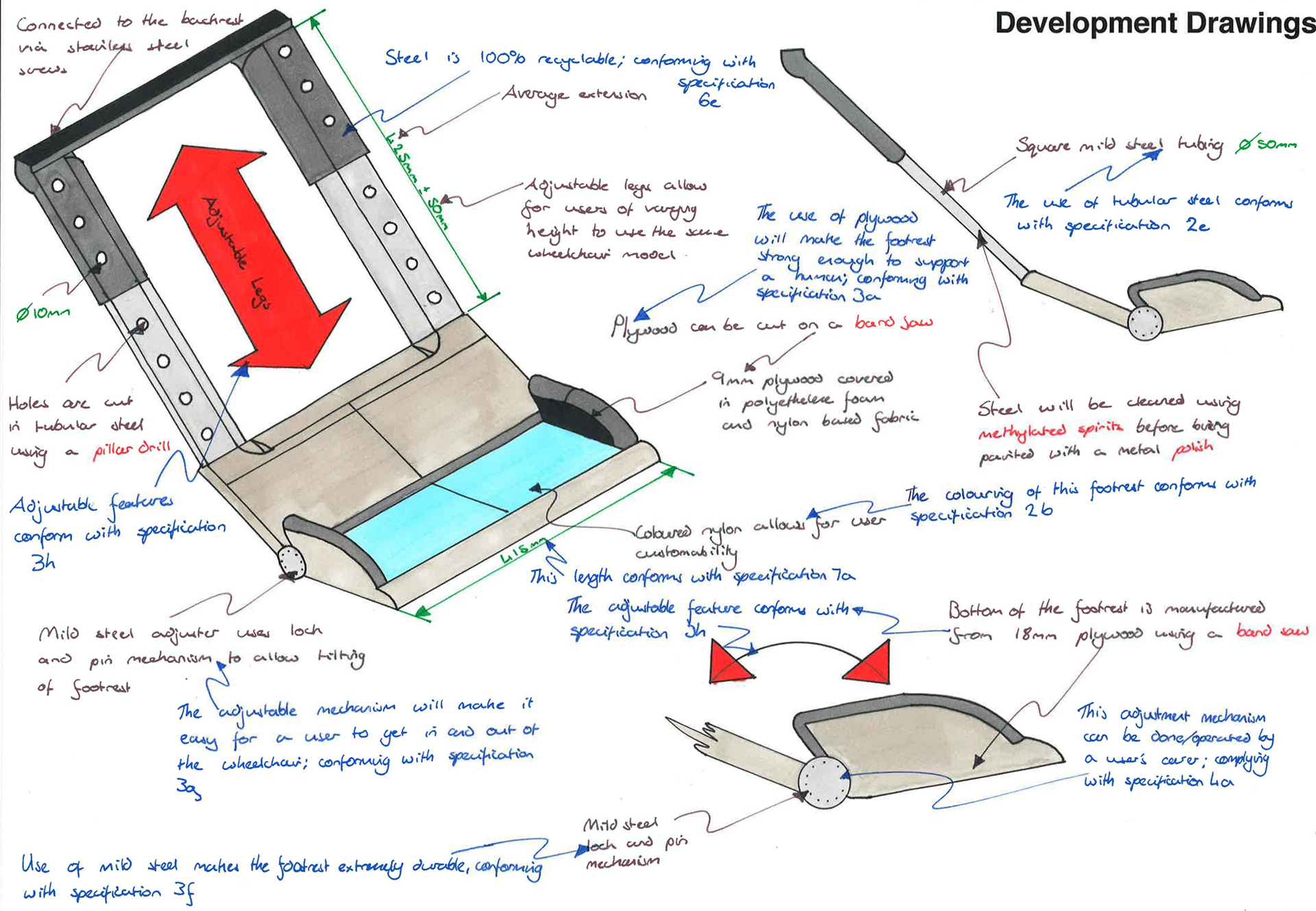

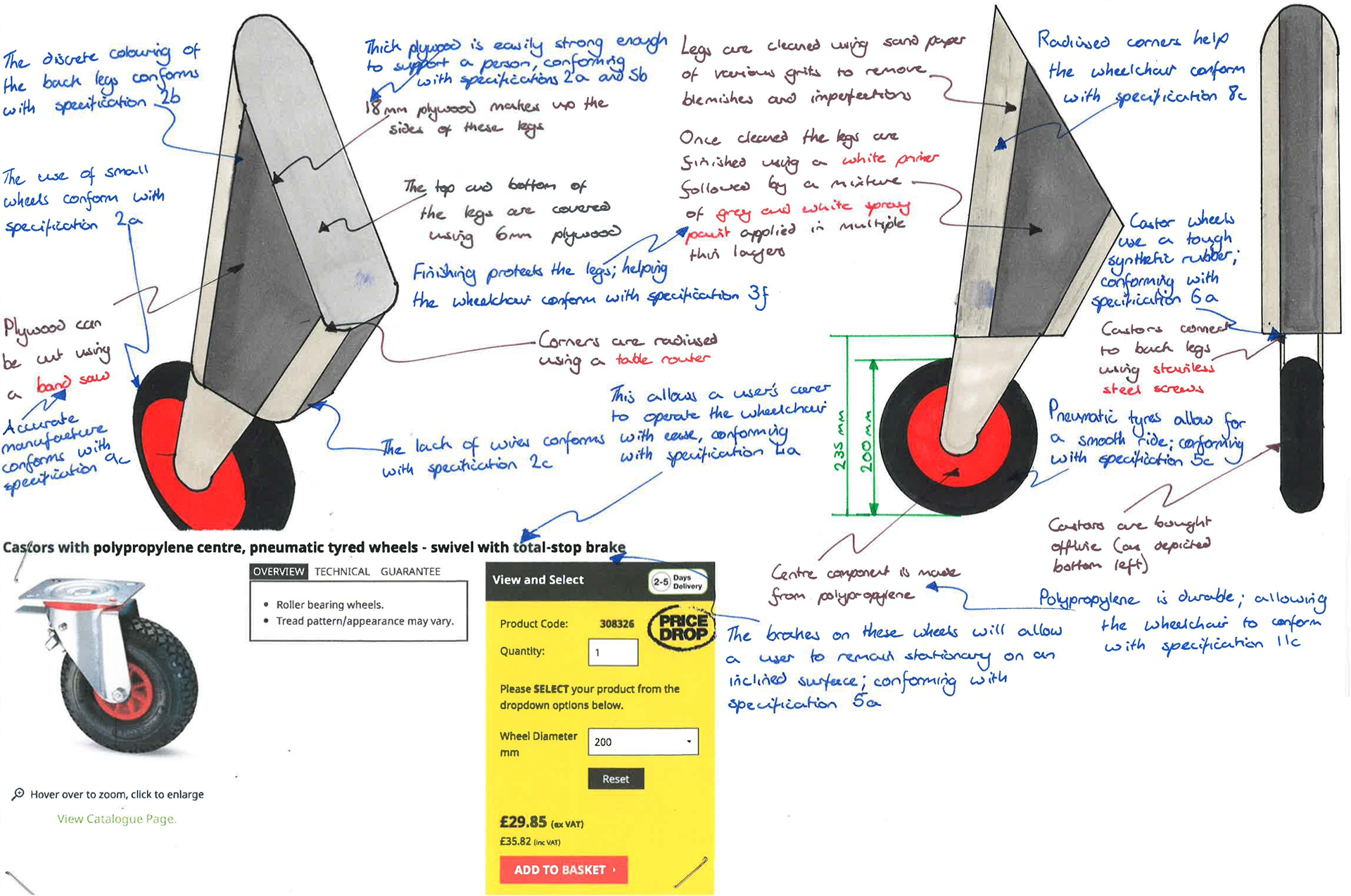

A deep dive into product features was created, allowing for final iterations and considerations to be brought to users for final selection.

Prototyping Final Iterations

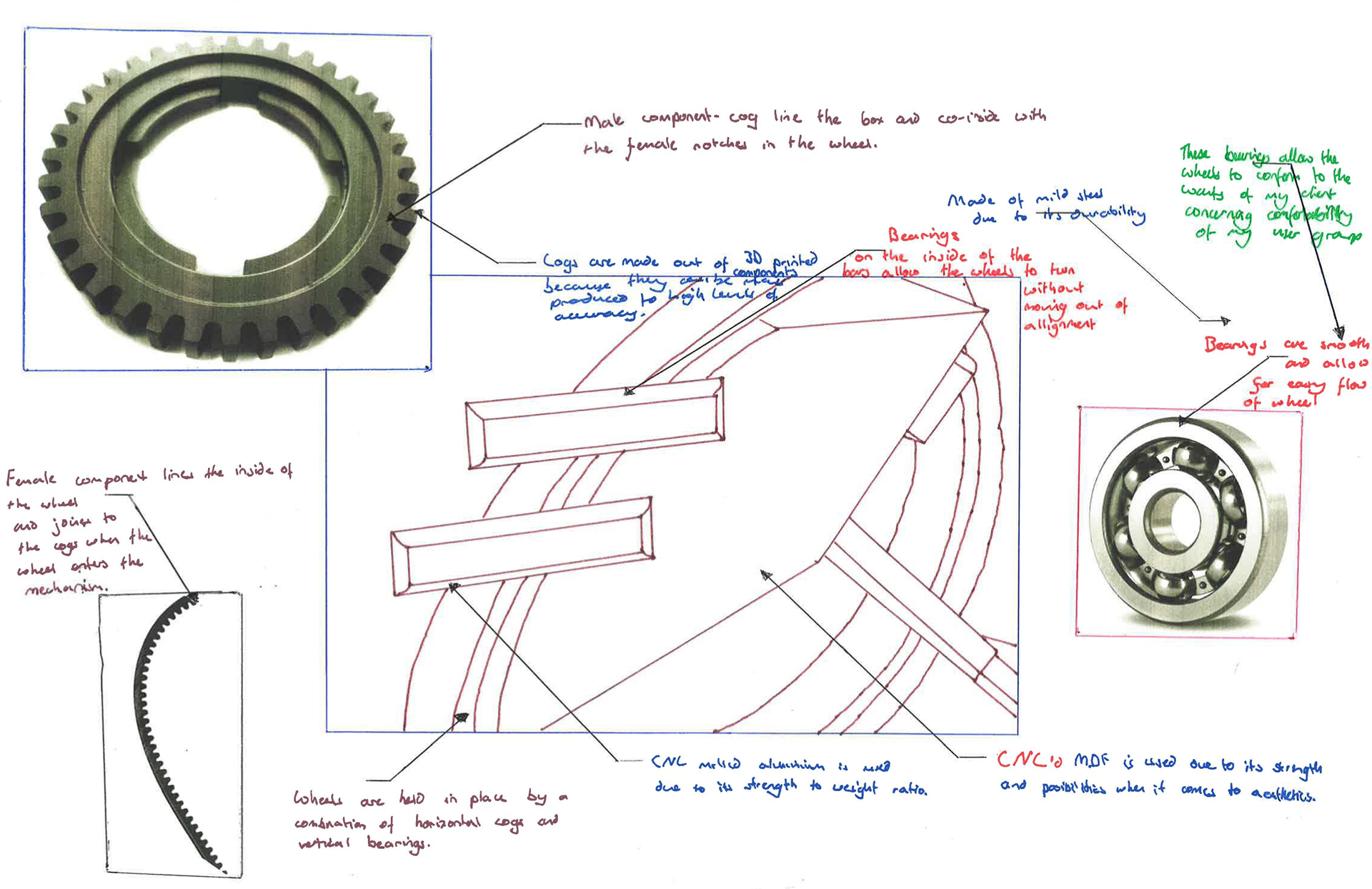

Ideas and concepts new to the wheelchair space that could not be easily validated by user opinions were physically prototyped and tested.

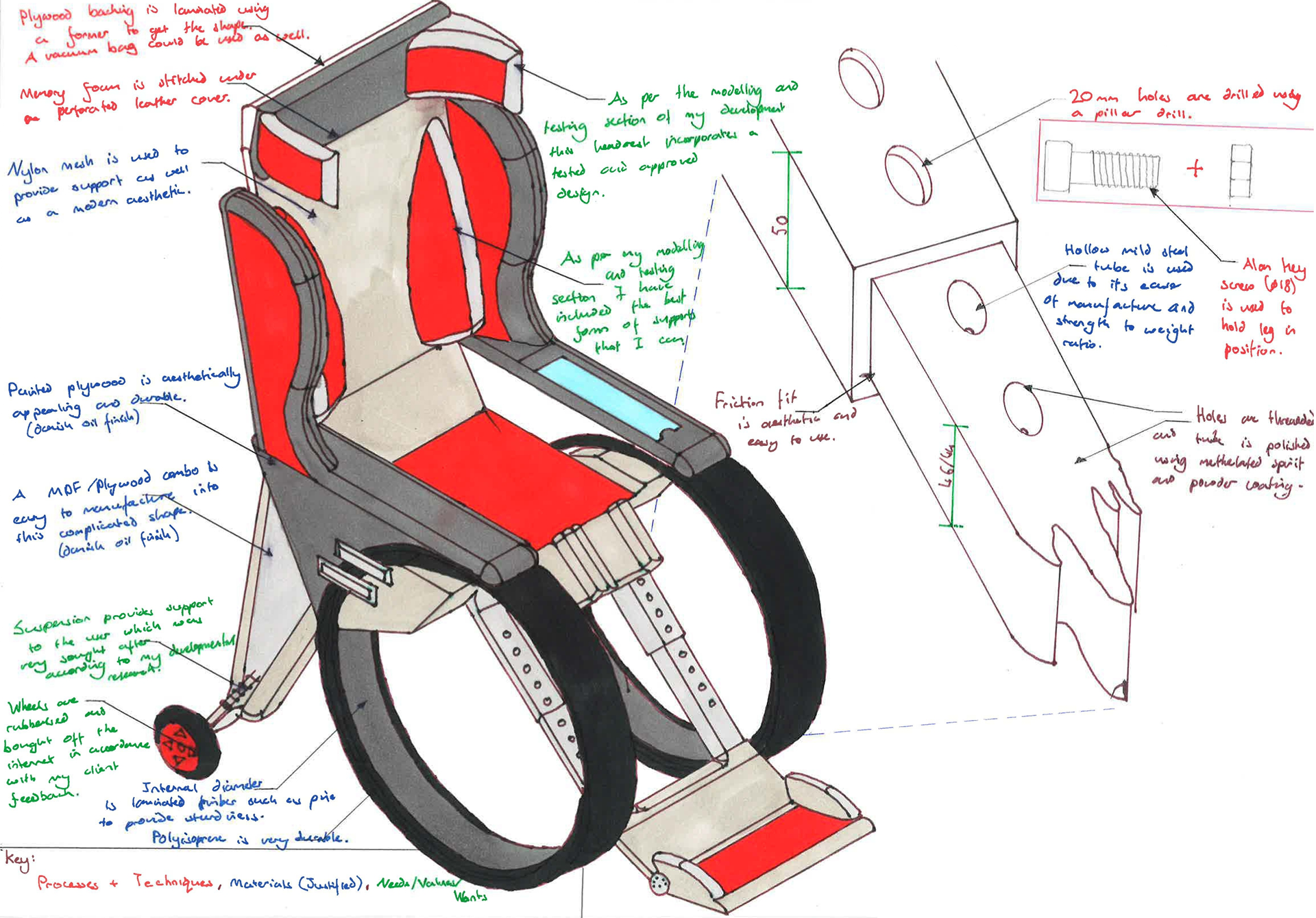

Sketching the Final Design

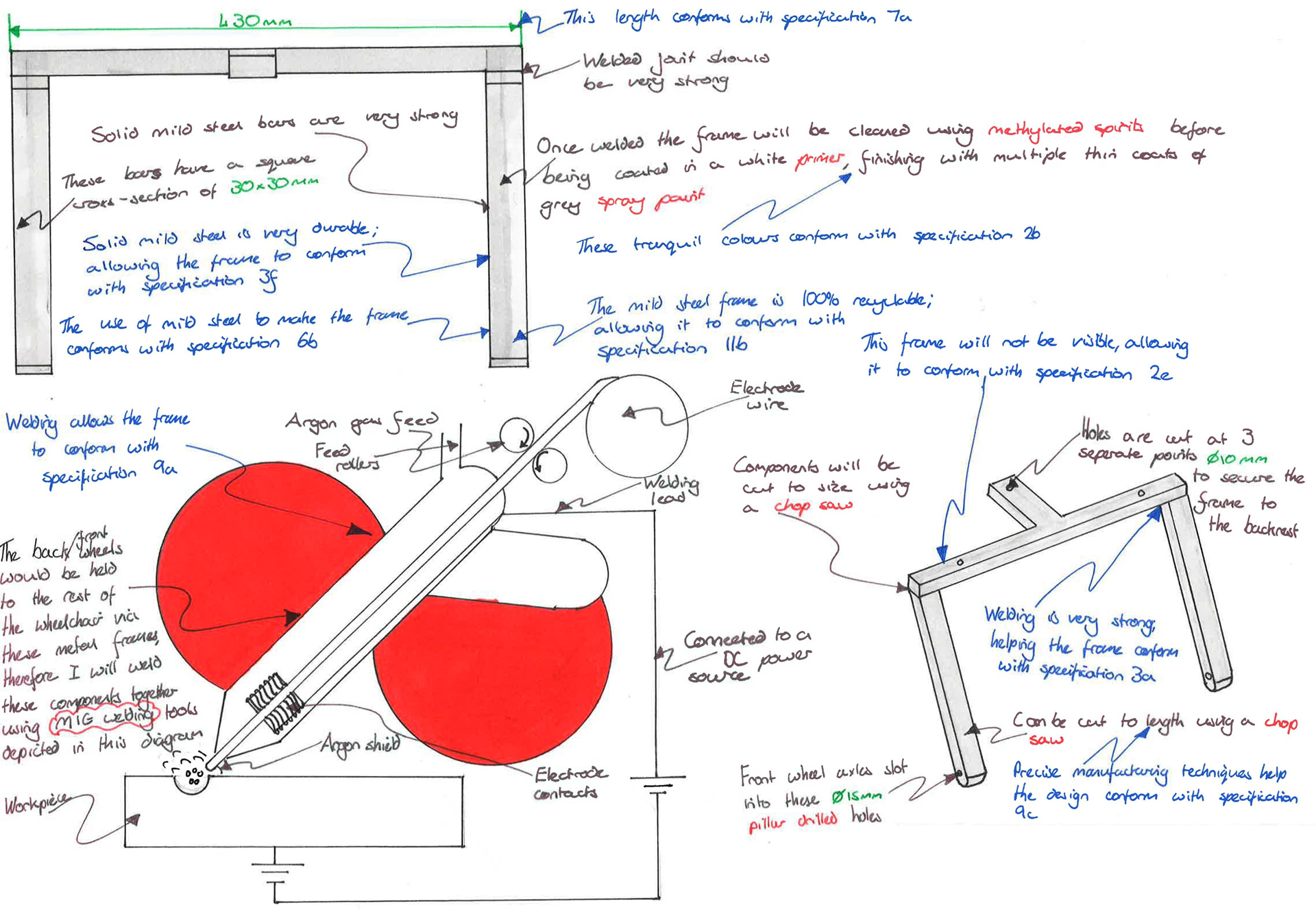

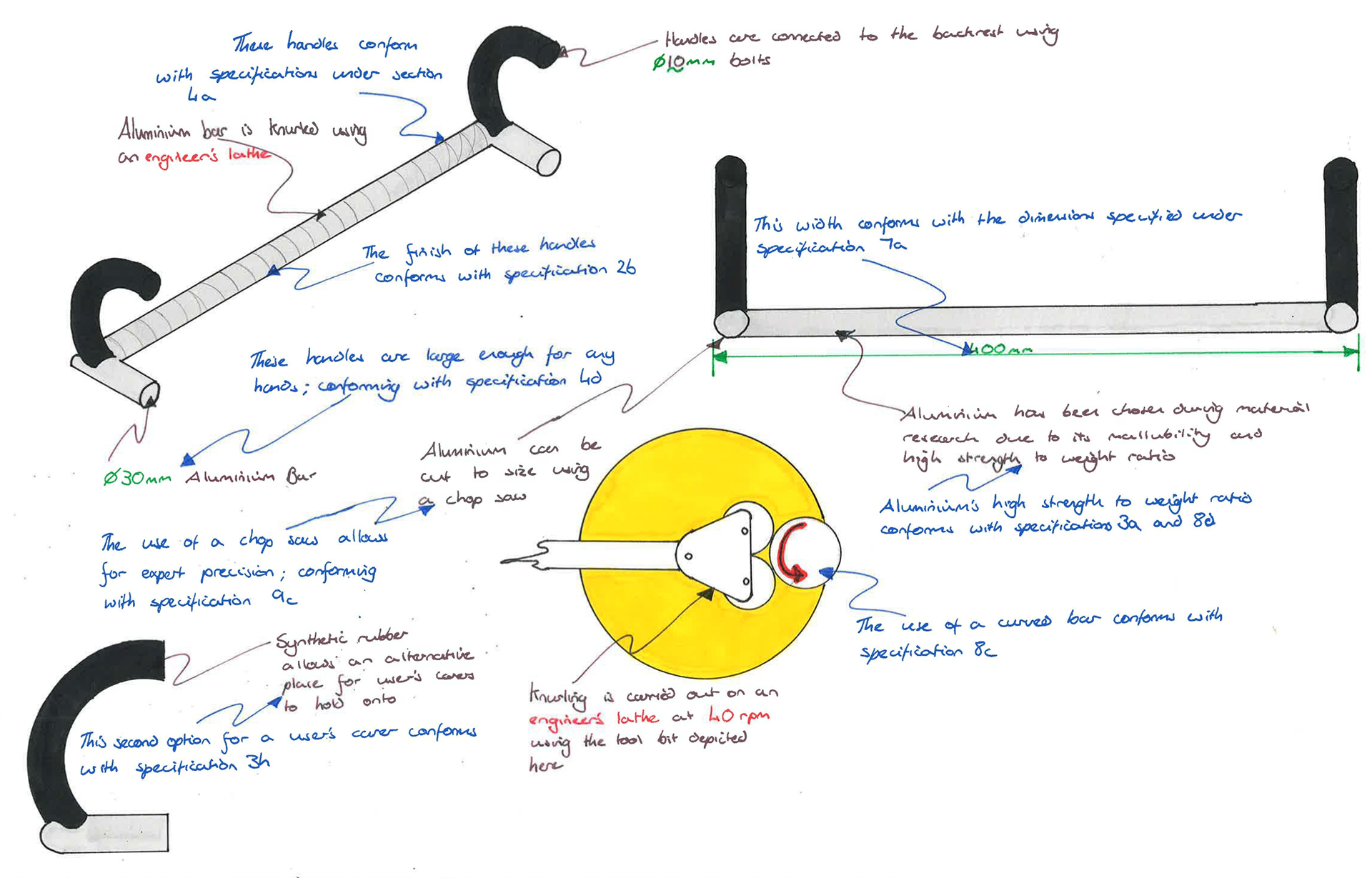

Bringing together everything that had been developed final sketches were created and notes of construction plans were detailed.

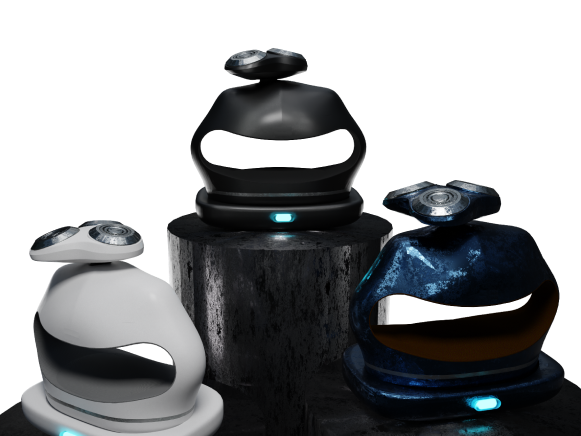

CAD of the Final Design

A computer-aided design and accompanying set of renders were created to act as a final touchpoint for users ahead of the upcoming manufacture of a final working prototype.

Manufacturing the Final Design

A fully functioning wheelchair was created from scratch using manufacturing methods including; welding, sewing, vacuum forming, cutting, milling, drilling, knurling, sanding, painting, and polishing, to name a few.

Once fully constructed the wheelchair was taken to users for product testing and review, with an overwhelmingly positive response. For the privacy and protection of those users involved no photographic evidence is available for public viewing.