The Thought Process

Bang and Olufsen is a world-renowned audio company that specializes in artistic audio technology that outperforms all competitors in its attention to detail and perfectionist approach. As such I felt that B&O had the opportunity to push its boundaries, extending its capture of the audio sector into the light sector as well.

The Hook

The way a person perceives a room is controlled by many factors, but the two most fundamental are what you see and what you hear. B&O already knows how to keep people listening, but the B&O Atmosphere aims to keep people watching as well, with a sculptural design that uses programmable LED lights to shine in any environment.

Mood Board Ideation

As with many other projects, mood boarding and research were fundamental first steps in understanding the scope of B&O.

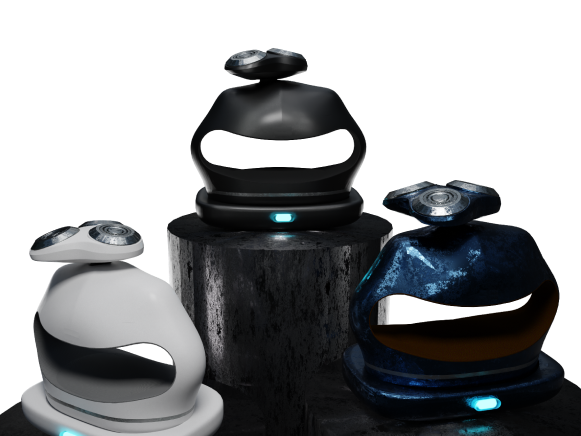

Physical Ideation

Once a design was created an effort to predict its manufacturing and electronics design was made.

Physical Prototyping

To replicate the aesthetic and understand the influence of the shape as a whole the B&O Atmosphere was physically prototyped using 3D printers and an MDF model covered in plastic, aluminum, and black felt.

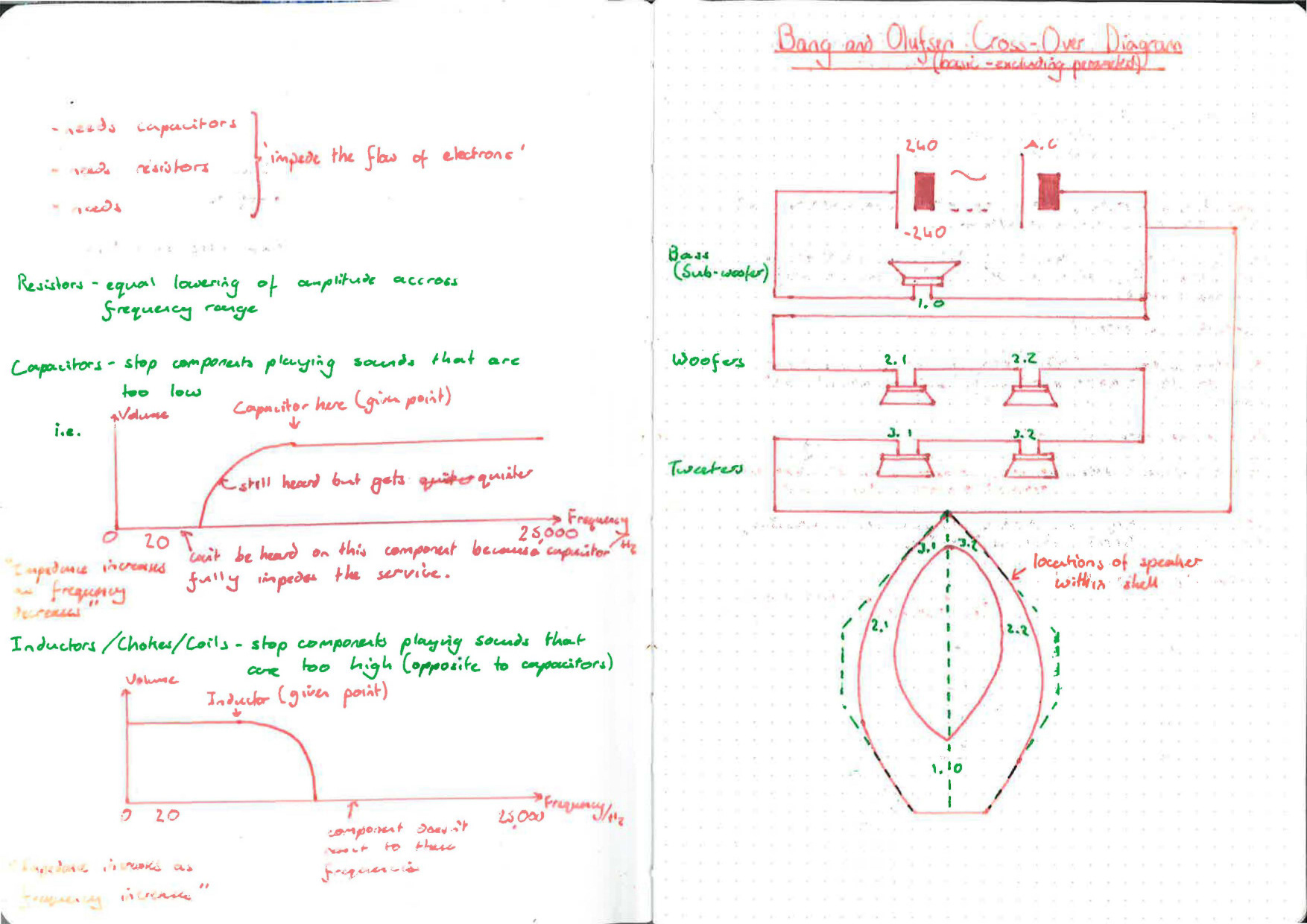

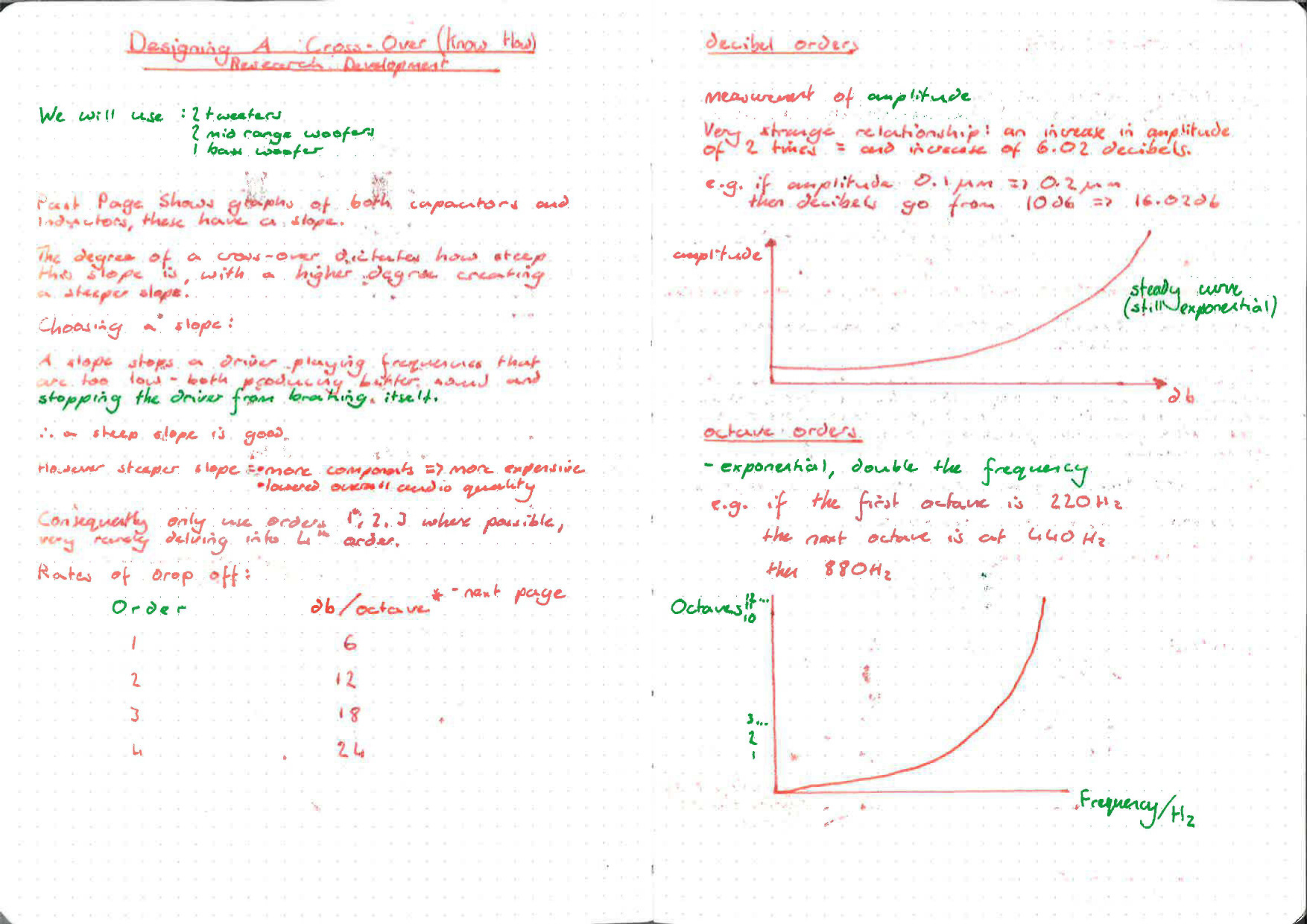

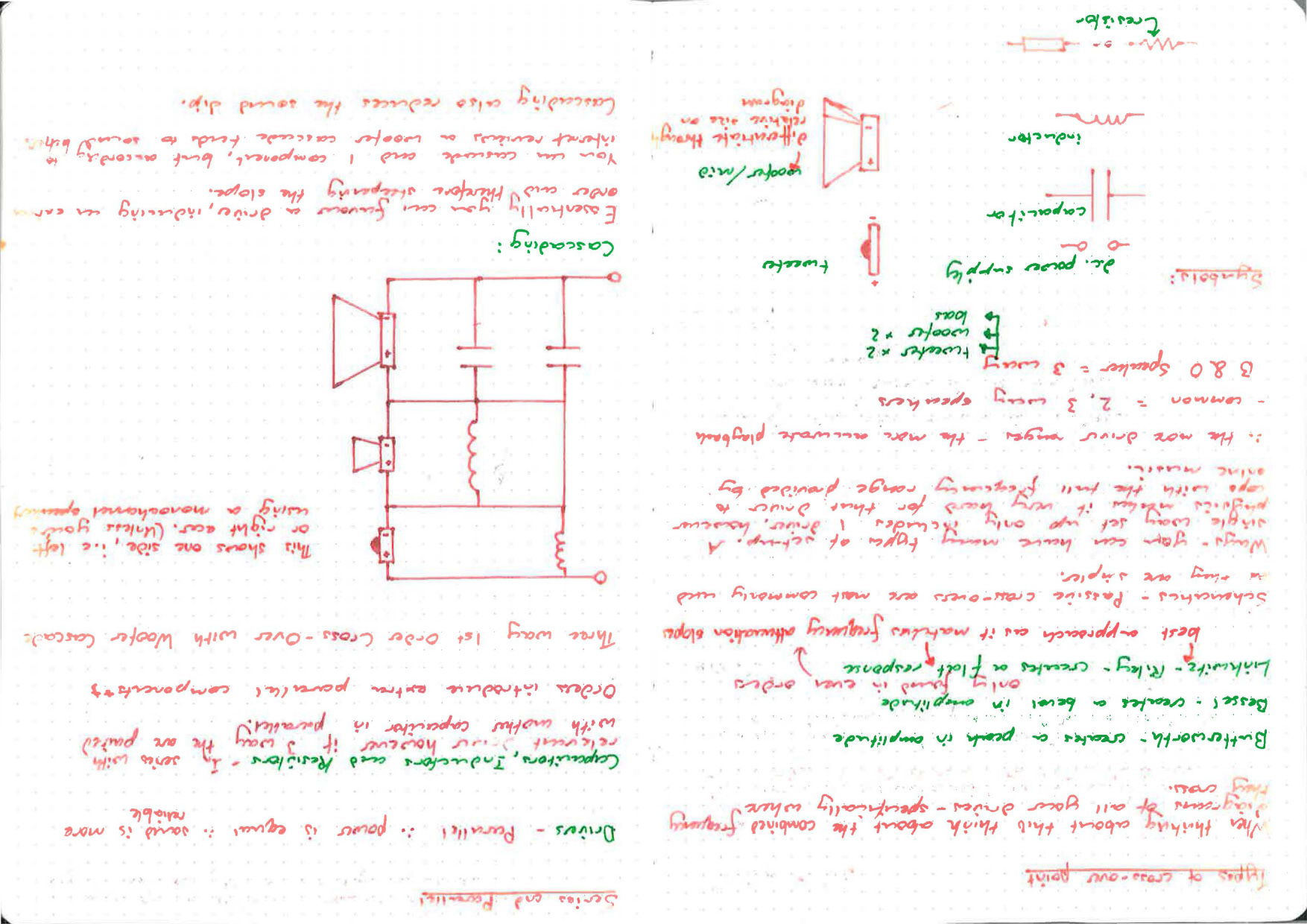

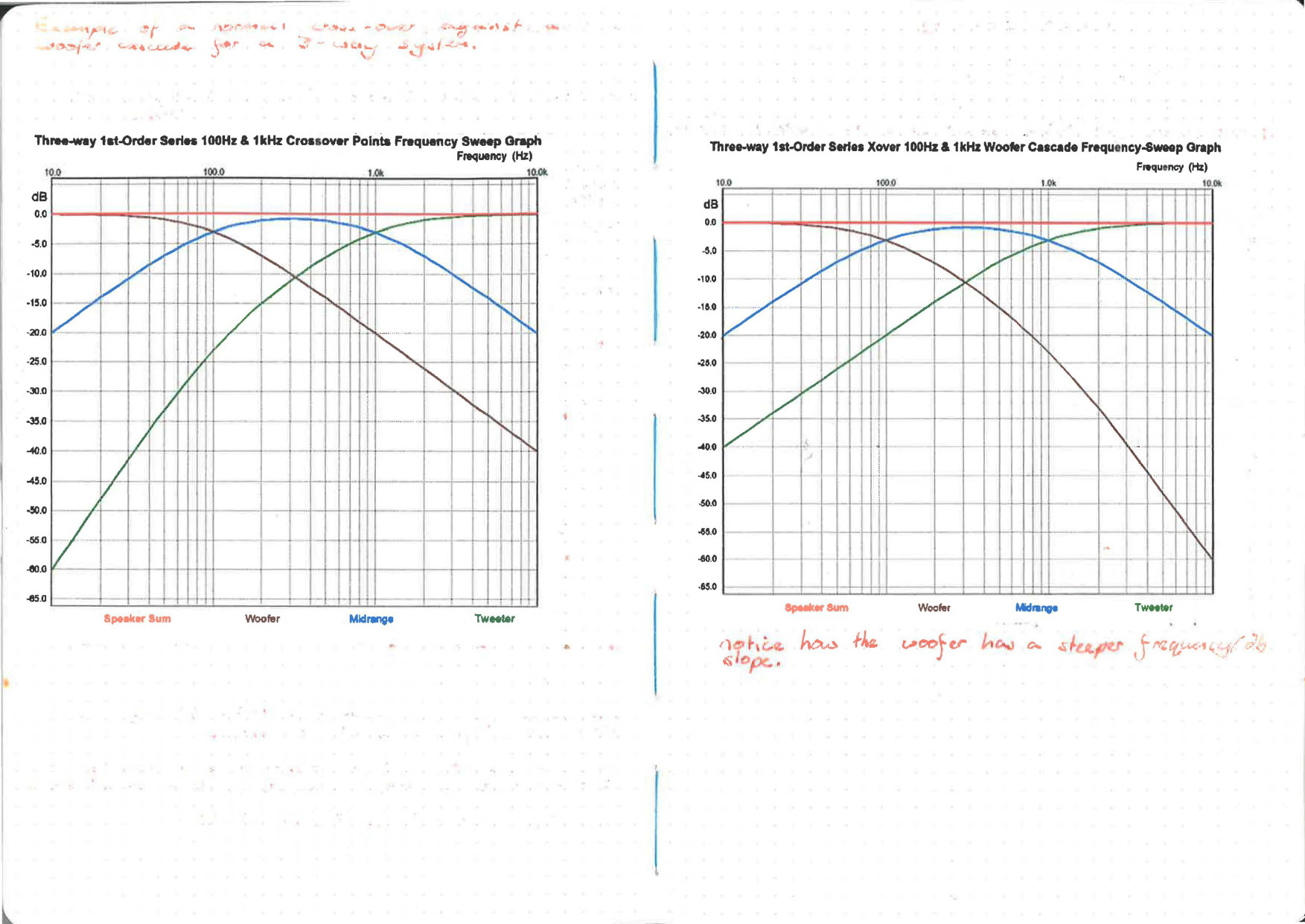

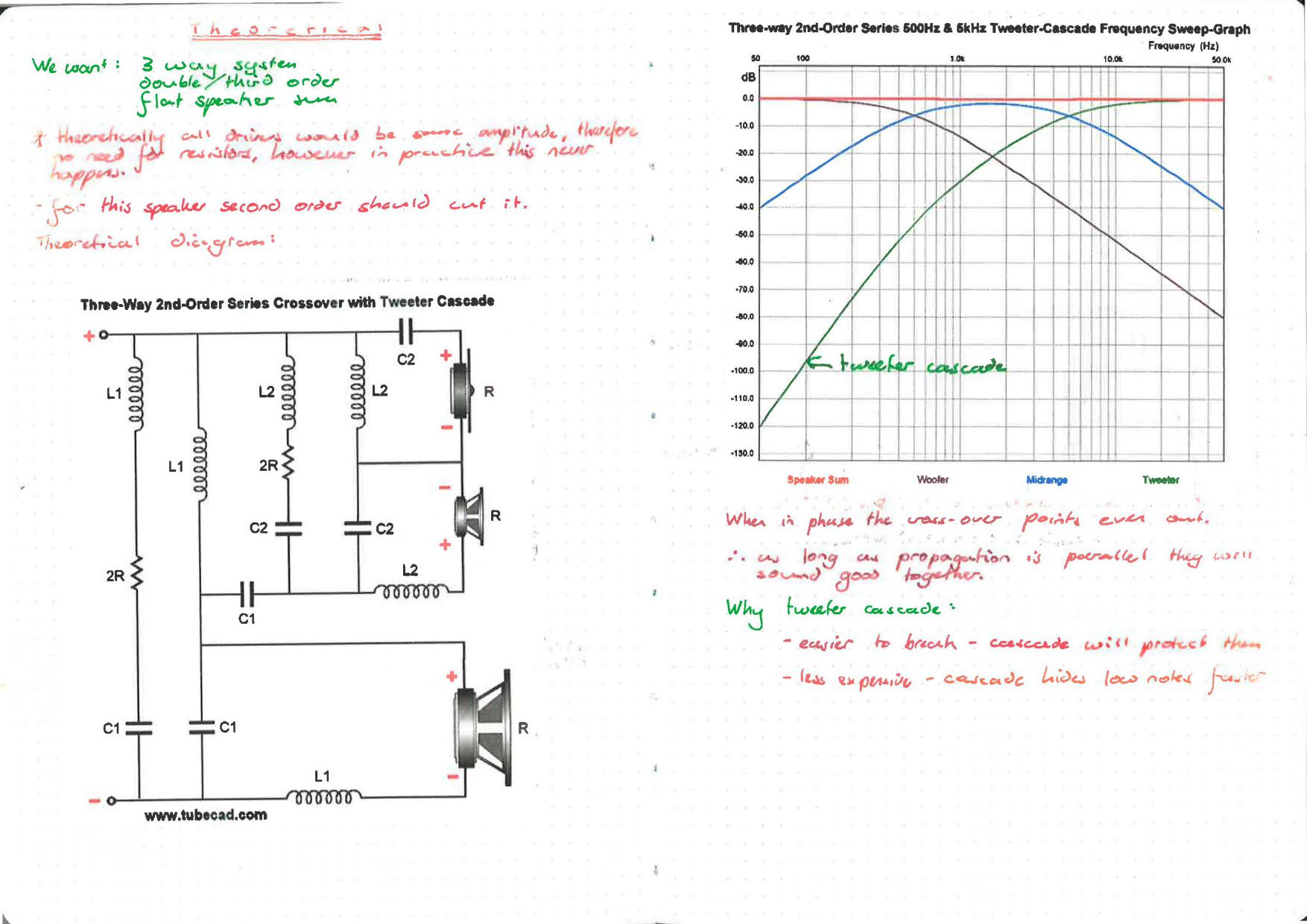

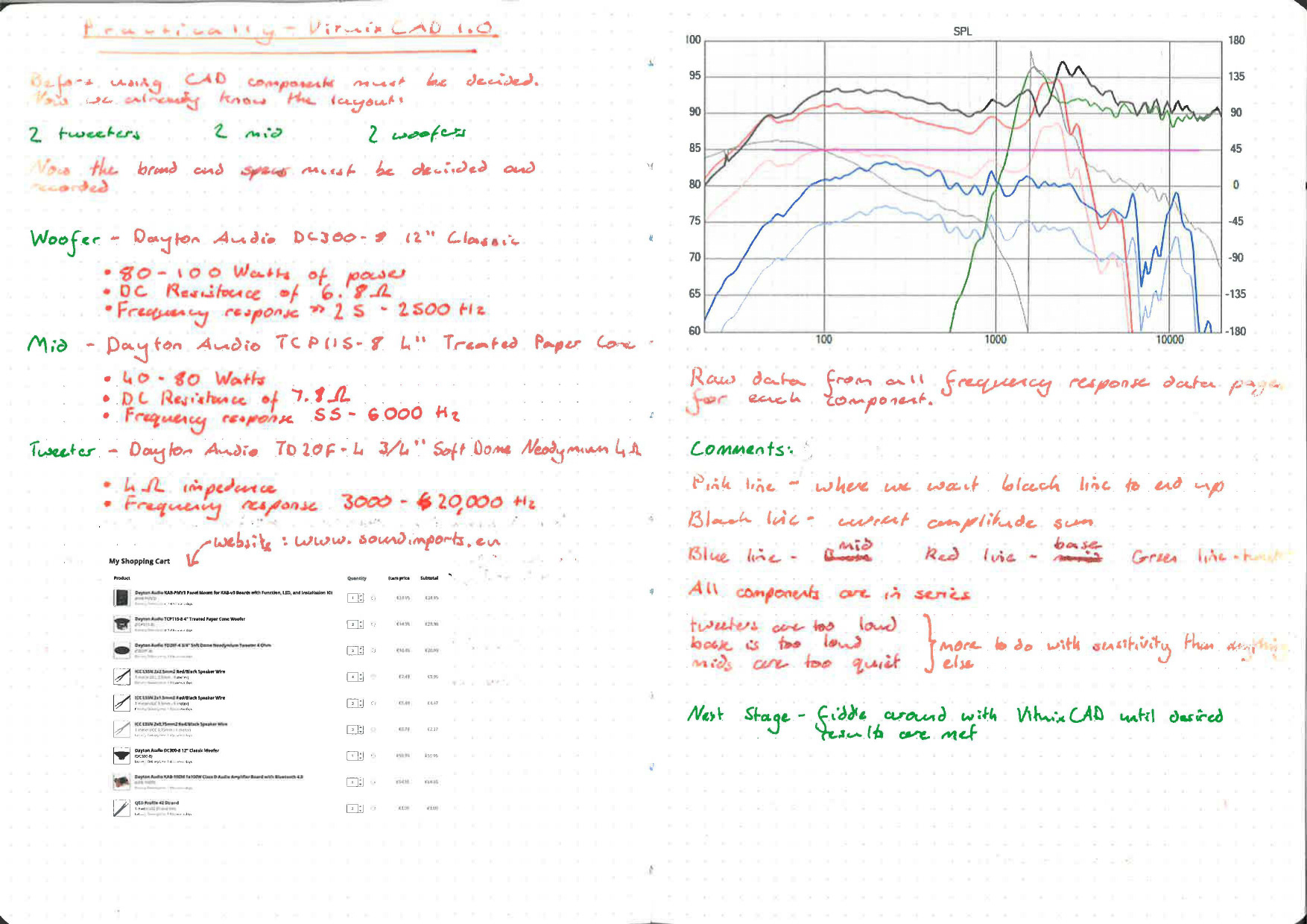

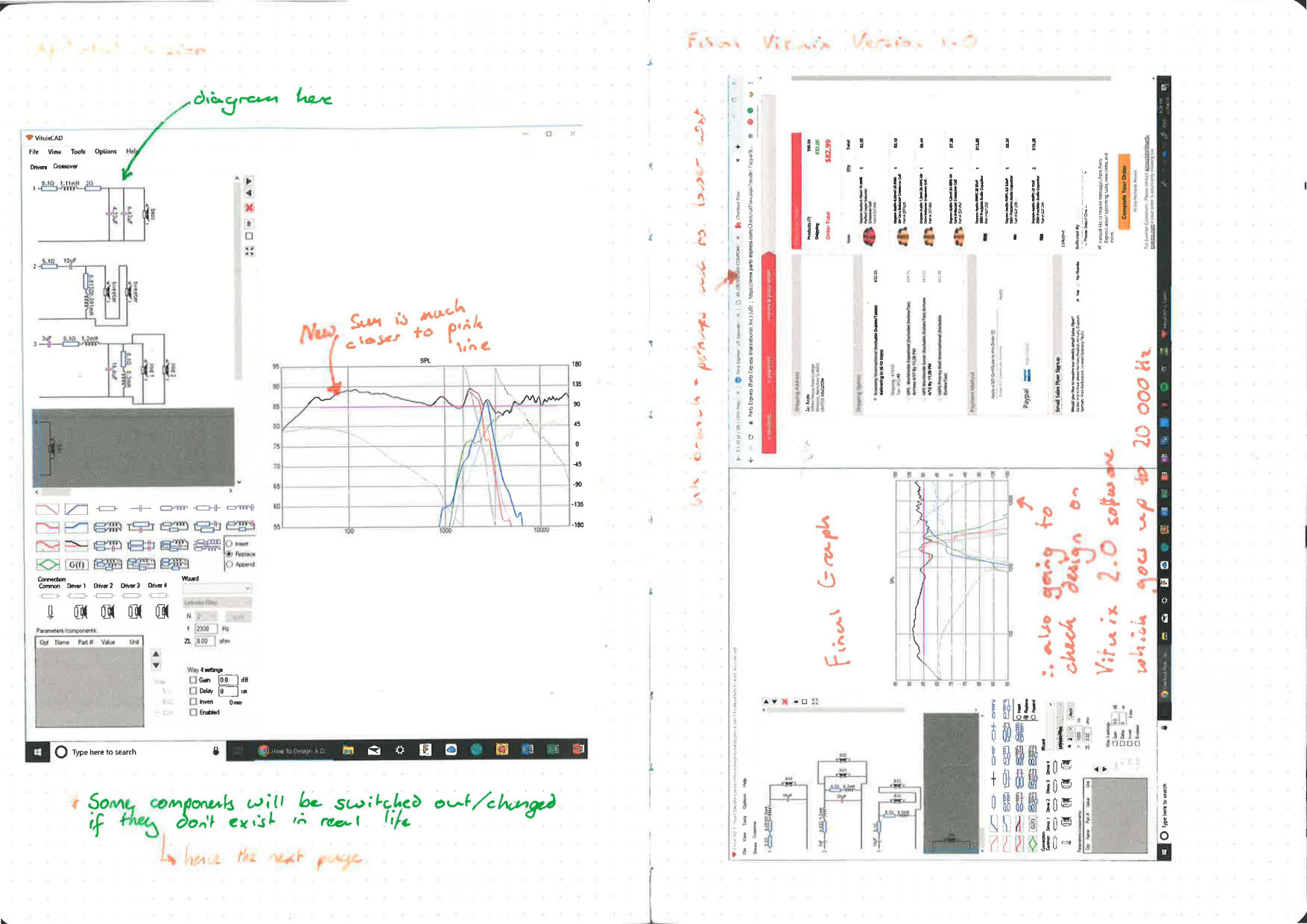

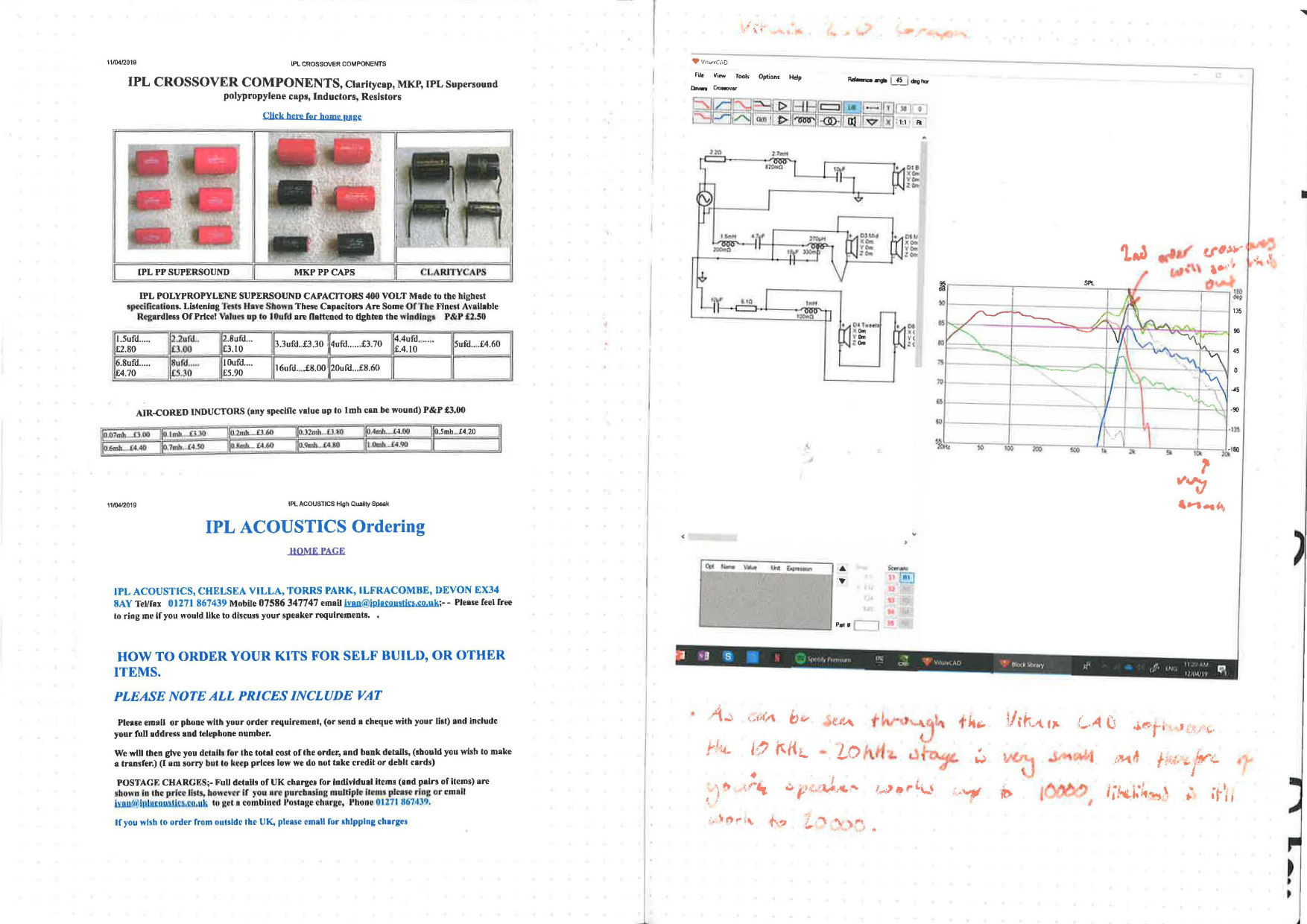

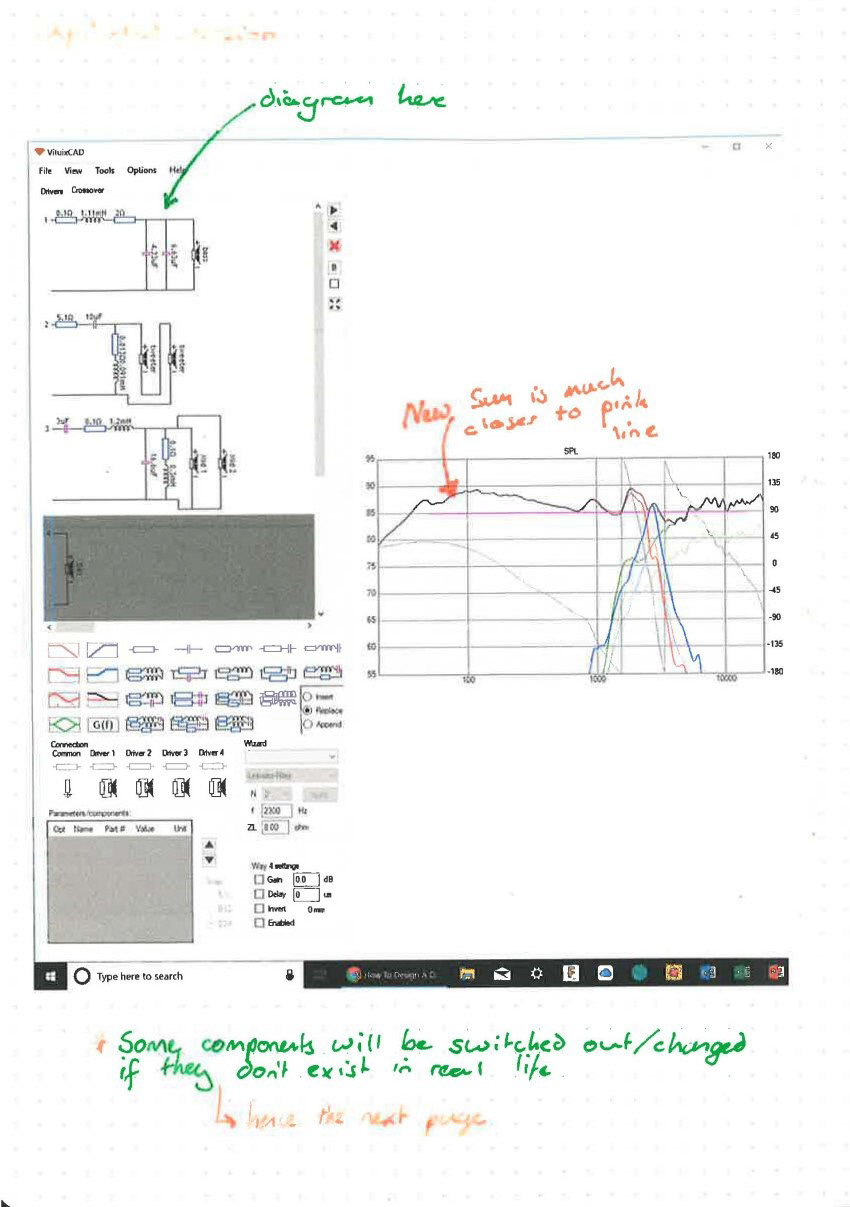

Electronics Design

The electronics design was created, to understand how speakers work and really deep dive into the work that Bang and Olufsen take so seriously. This was not a prerequisite for the competition, but I felt it was an amazing way to truly connect with what I was building ahead of my plans to create a full-scale prototype.

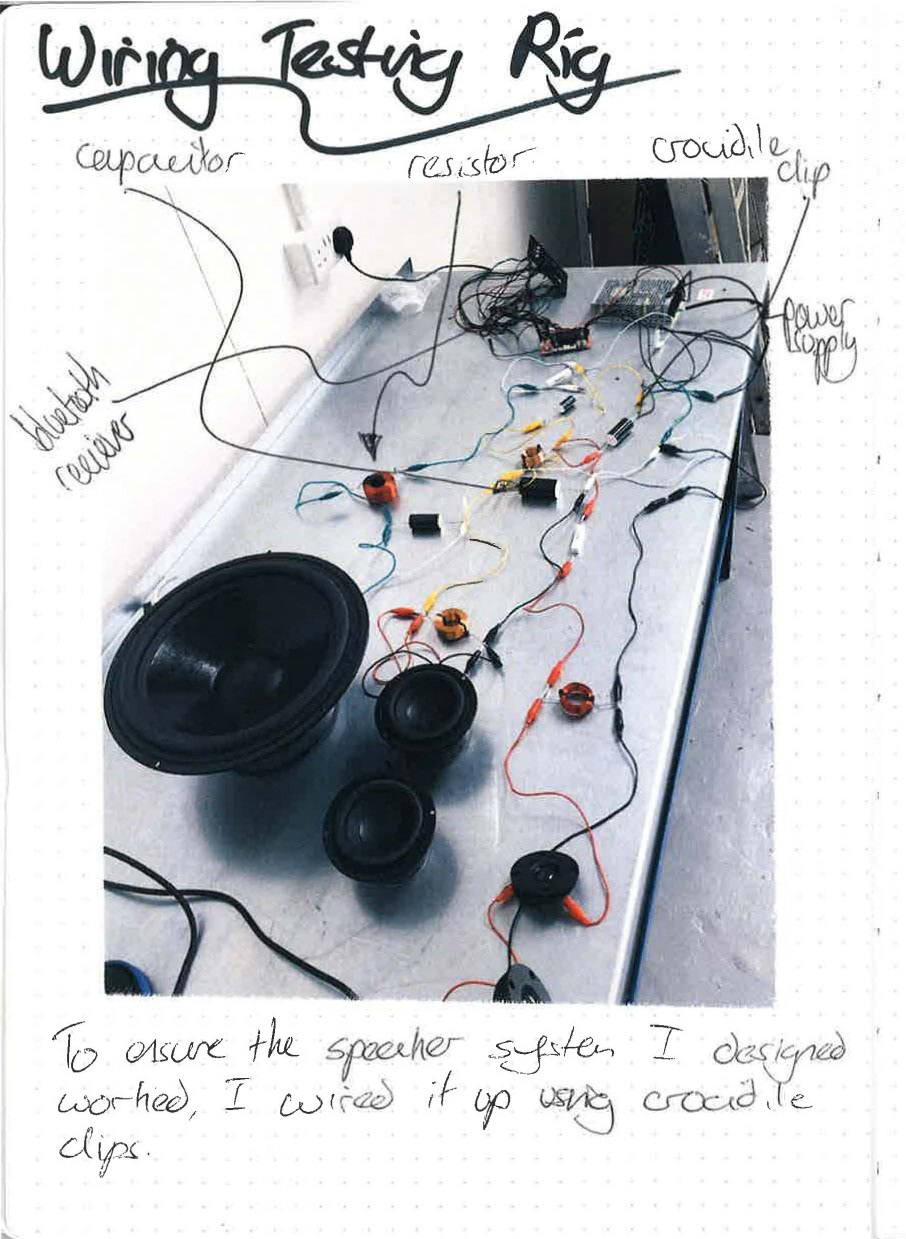

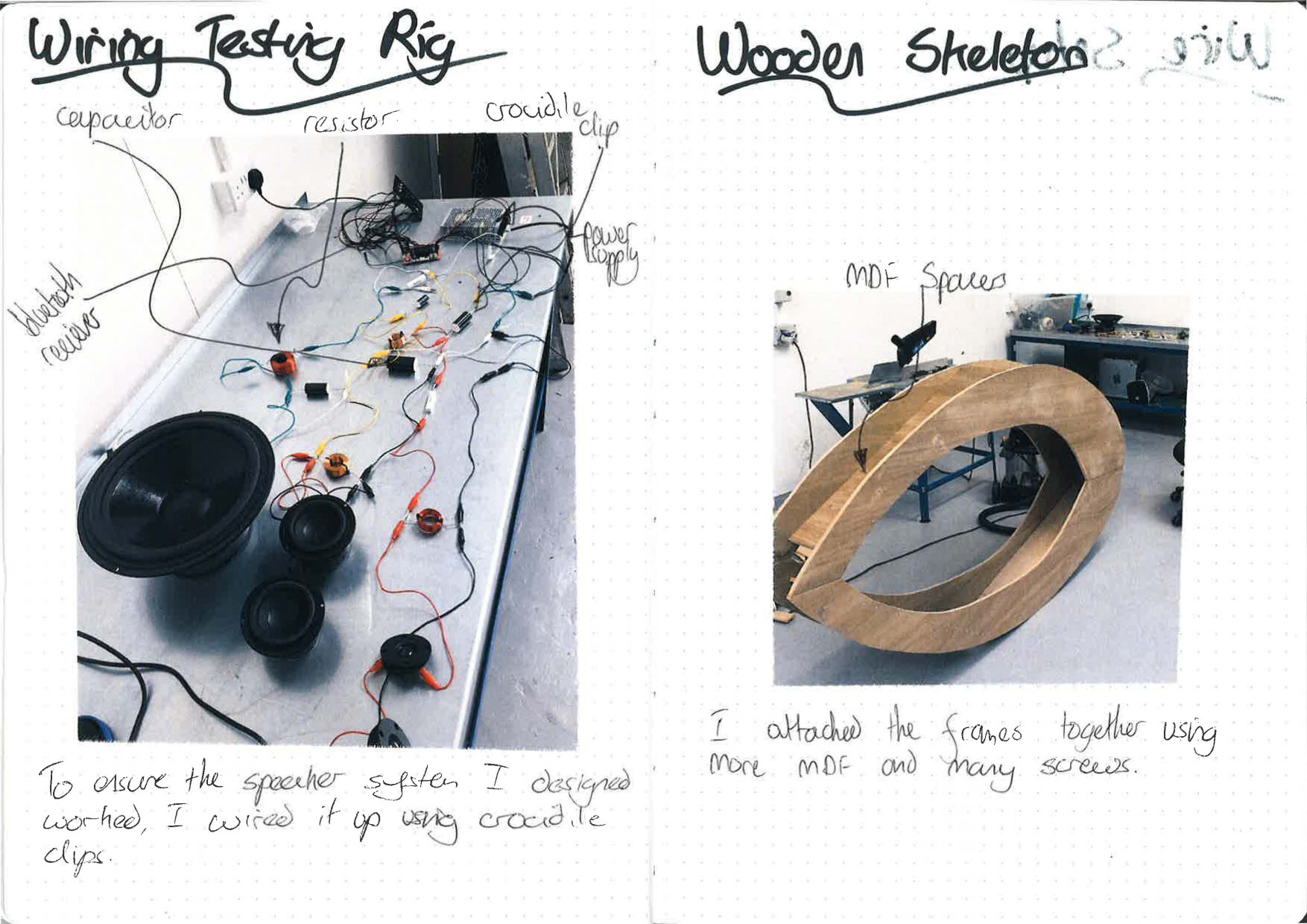

Electronics Testing

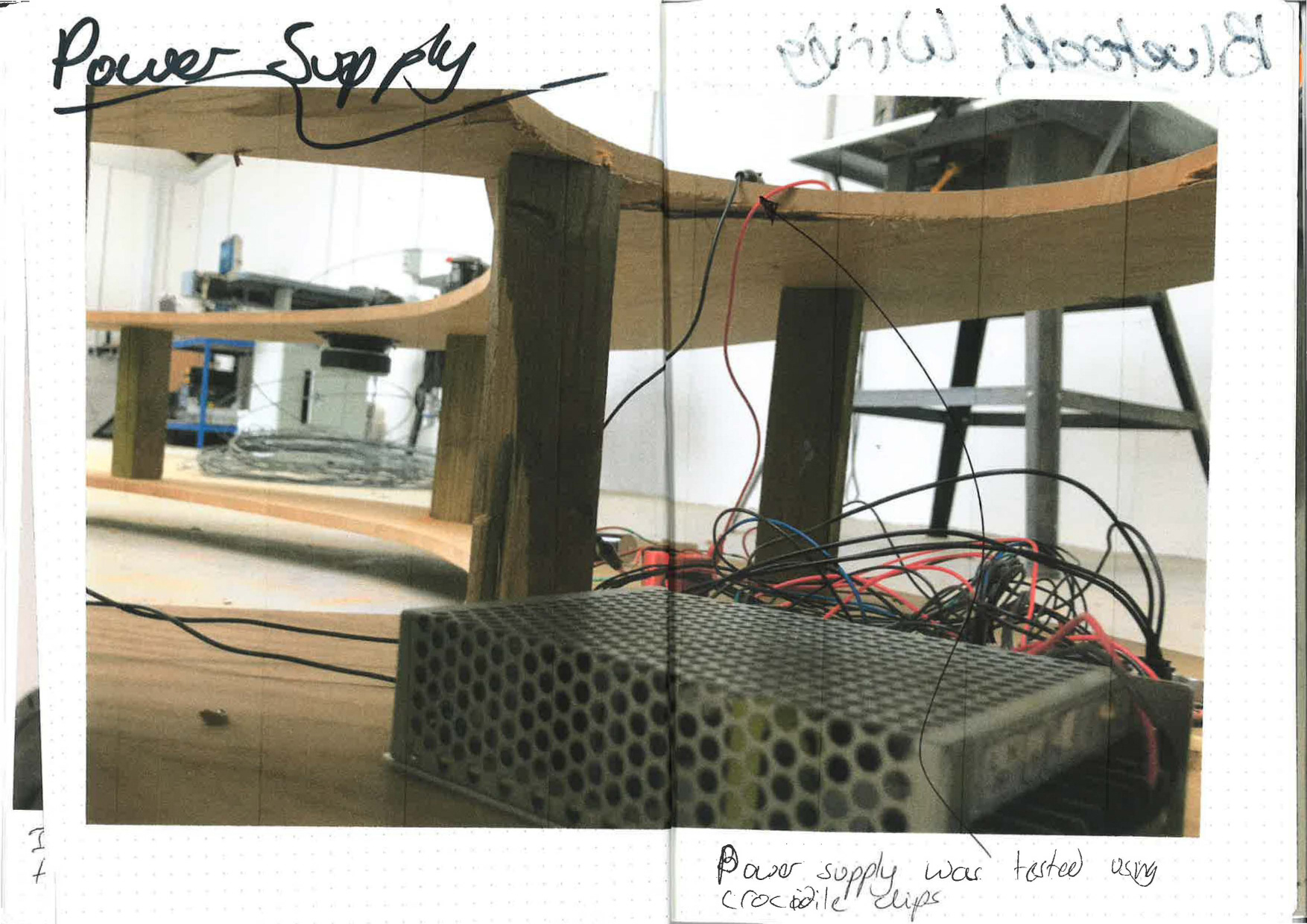

The electronics I designed were physically tested. Temporary connections were fitted initially in an effort to "measure twice, cut once."

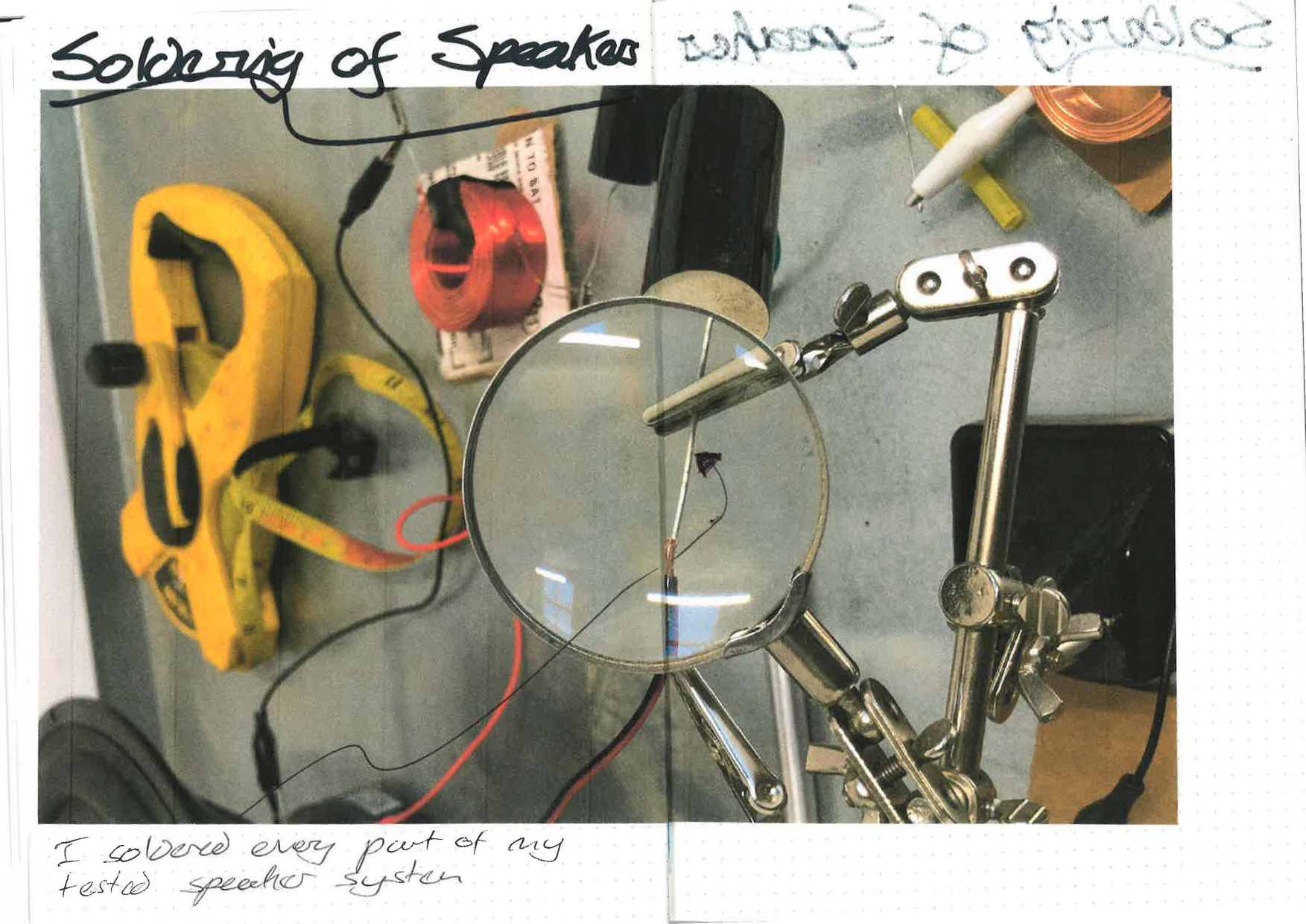

Wire Soldering

Once a satisfactory testing demonstration was achieved, soldering was undertaken to finalise the connections.

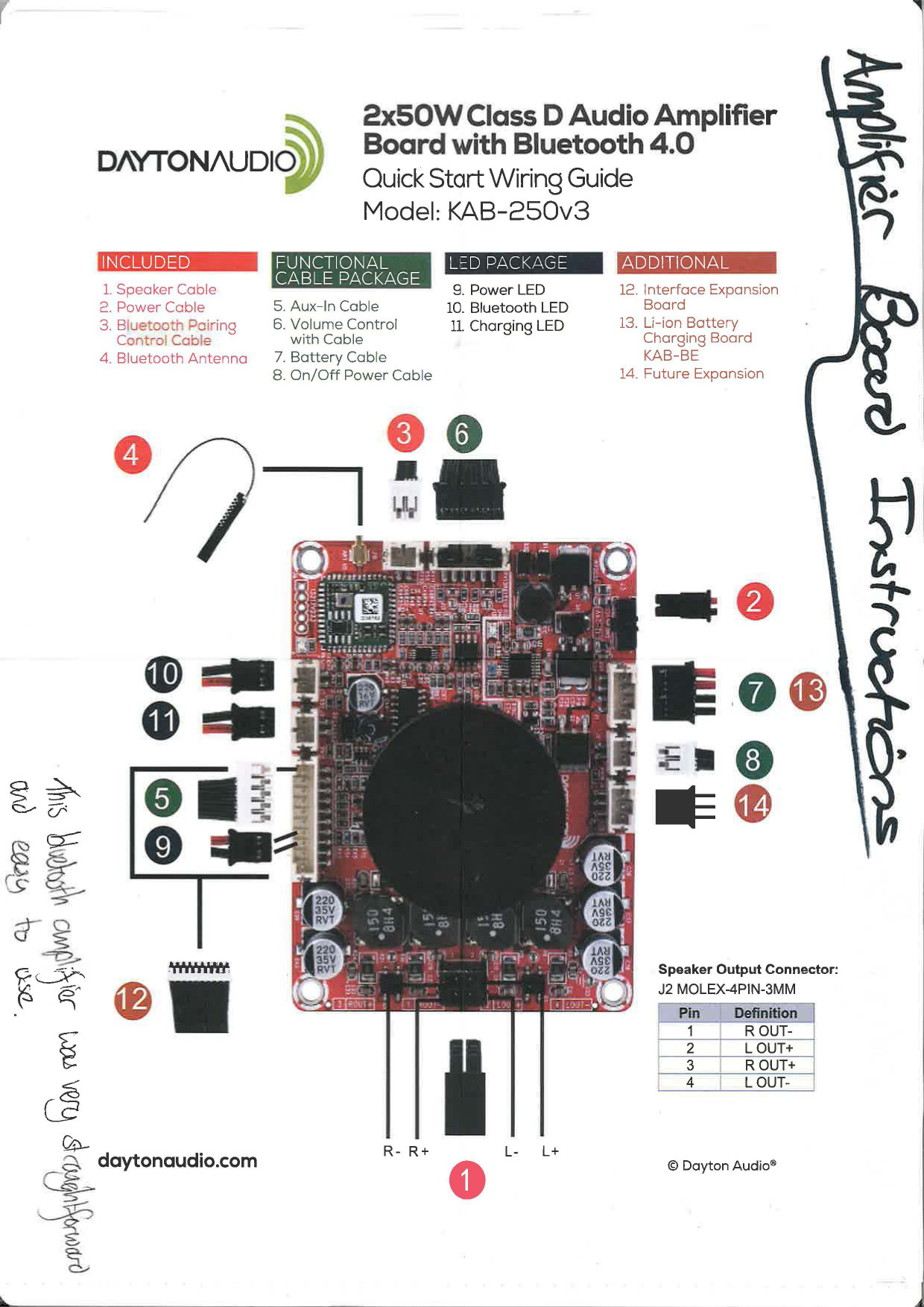

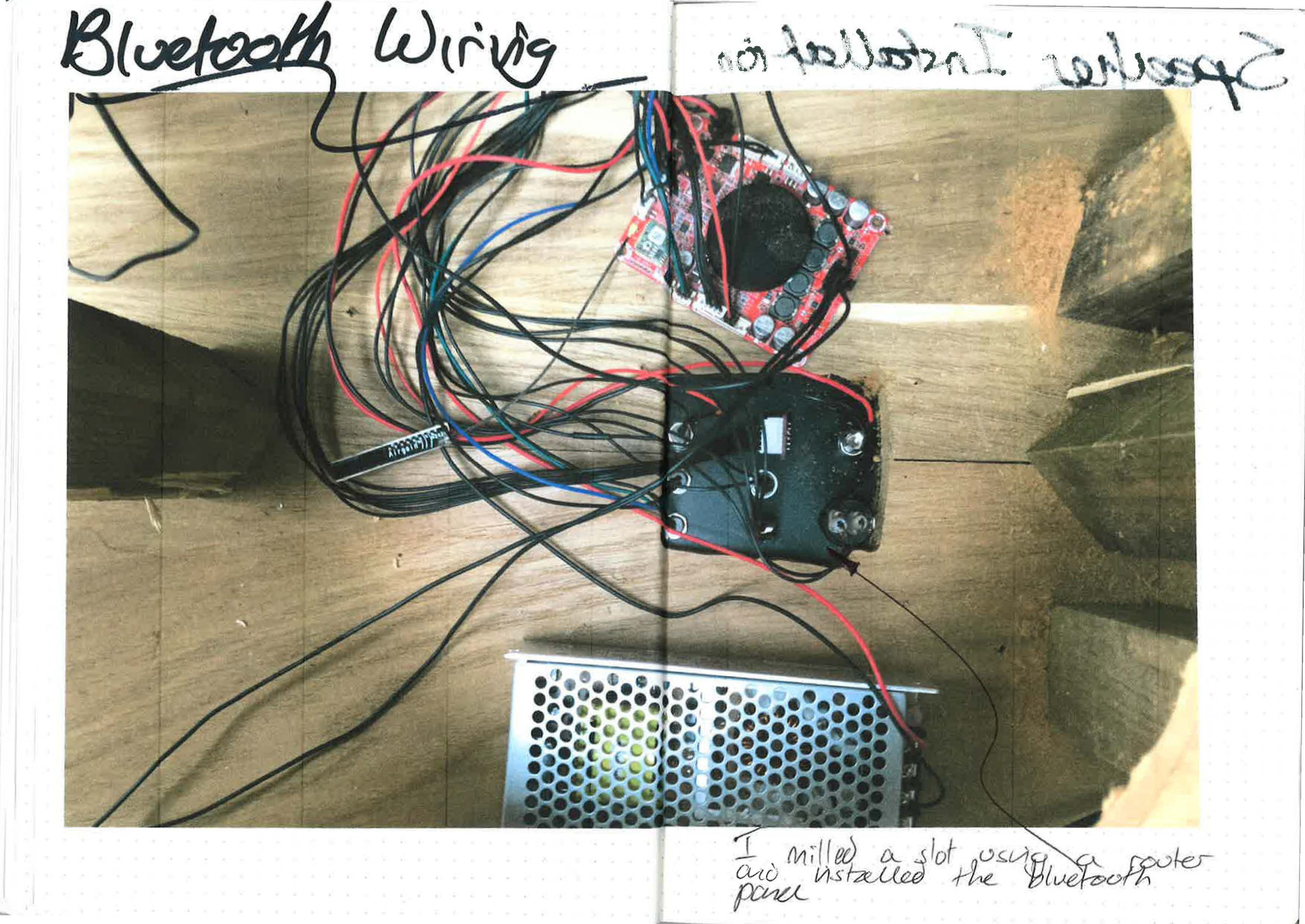

Bluetooth Integration

A Bluetooth receiver was fitted to the speaker mechanism, as I wanted this design to be as sleek as possible and thus wanted to avoid a wired connection to any input devices.

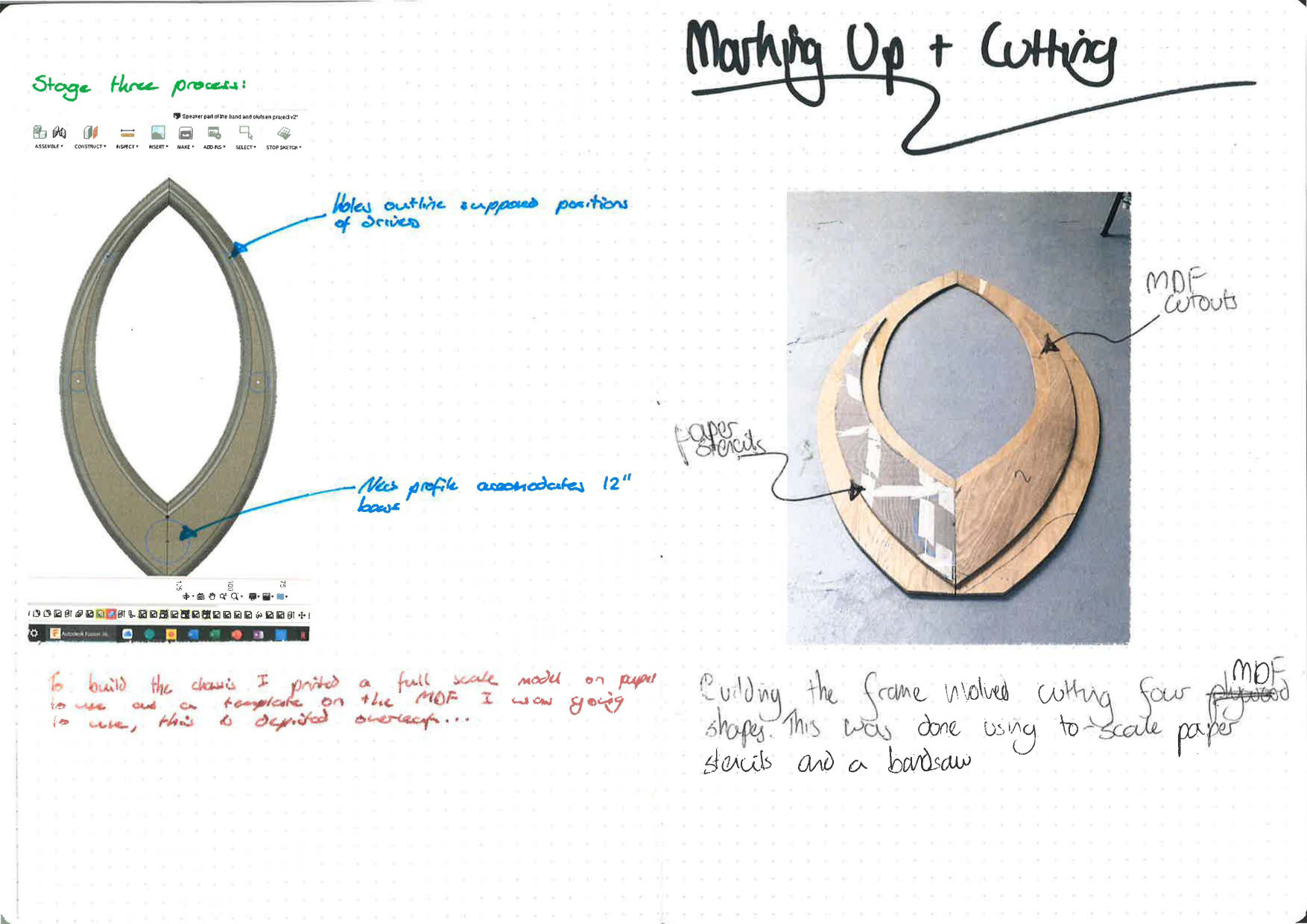

Frame Manufacturing

The frame is hidden and the prototype was very large, so manufactured board in the form of MNF was selected as a suitable candidate for a material, given that the slabs come in 2.4mx1.2m sizes.

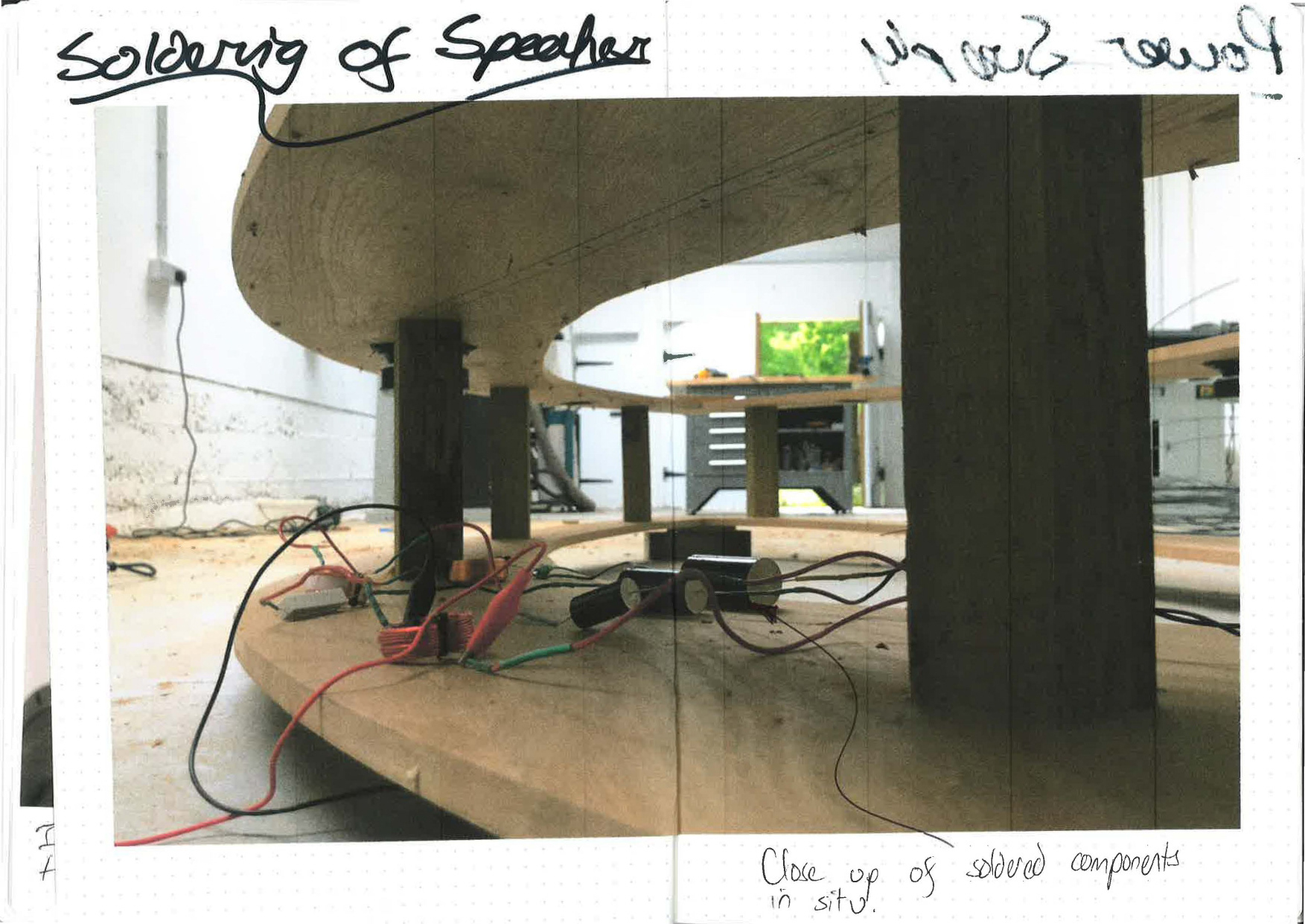

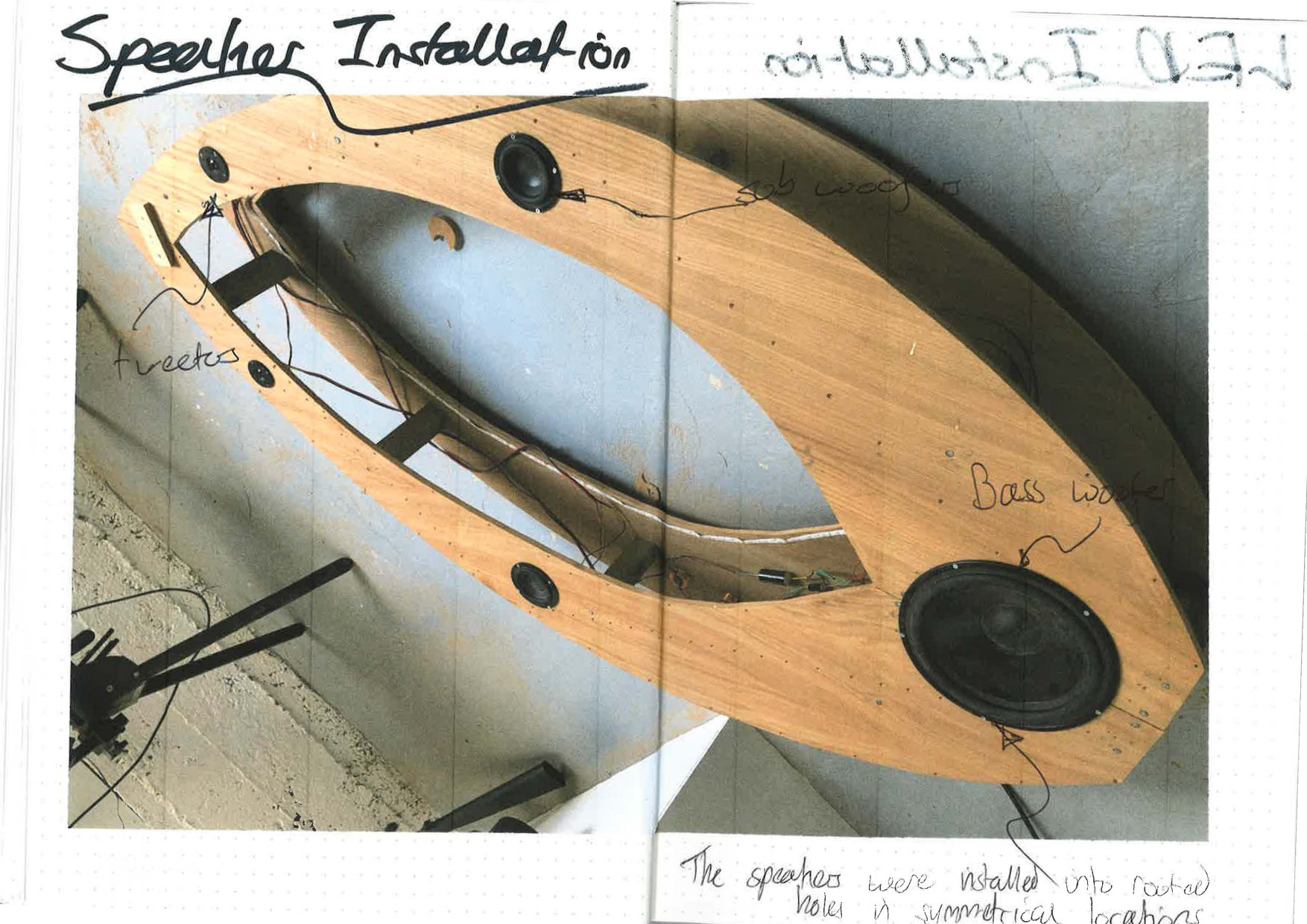

Speaker Implementation

Speakers were secured into the frame, starting the journey towards a fully functioning speaker system. Fewer speakers were implemented than in the original design since this was a prototype built within a budget, something that is not easily forgiven by the hefty price tag of high-quality audio parts.

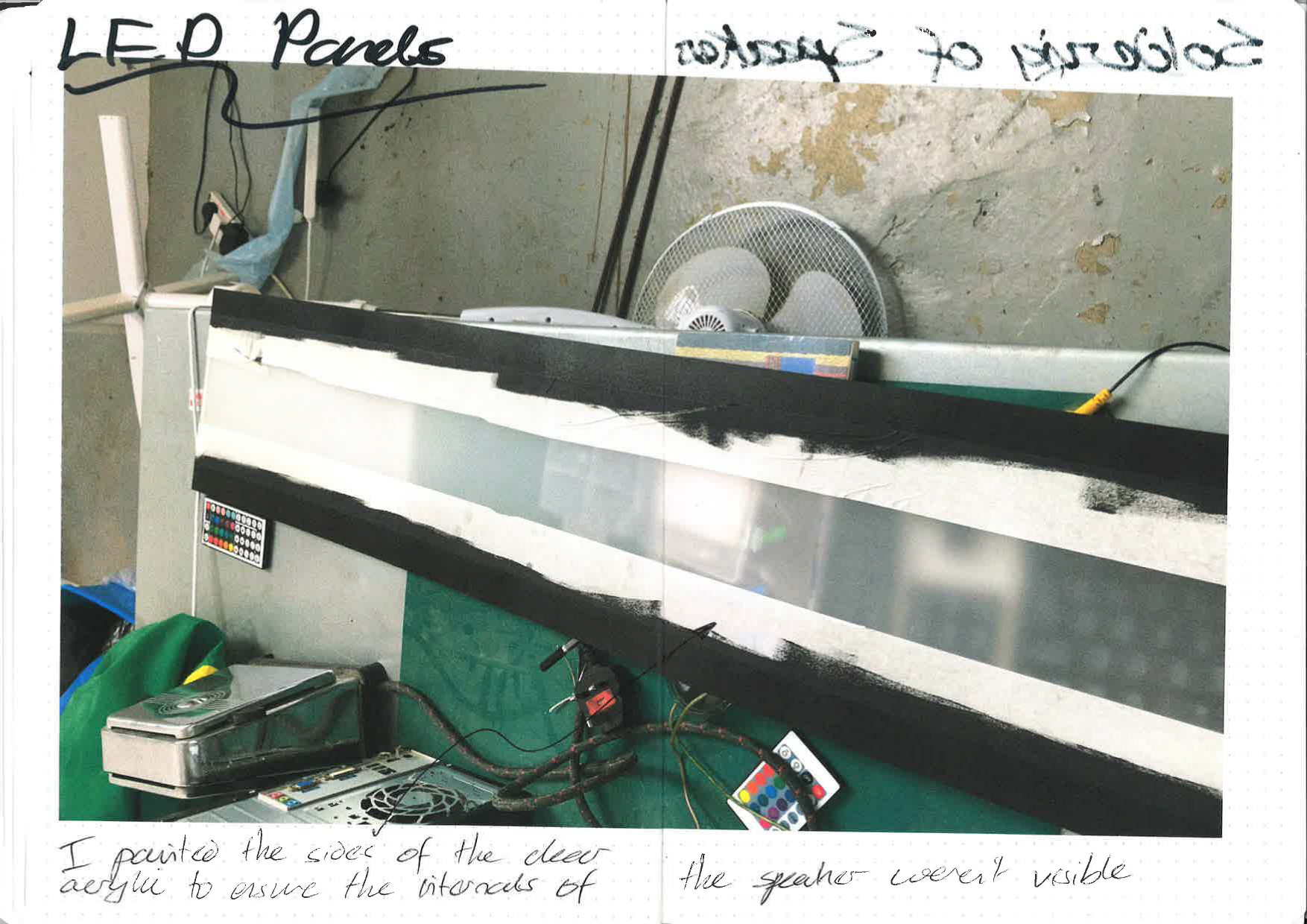

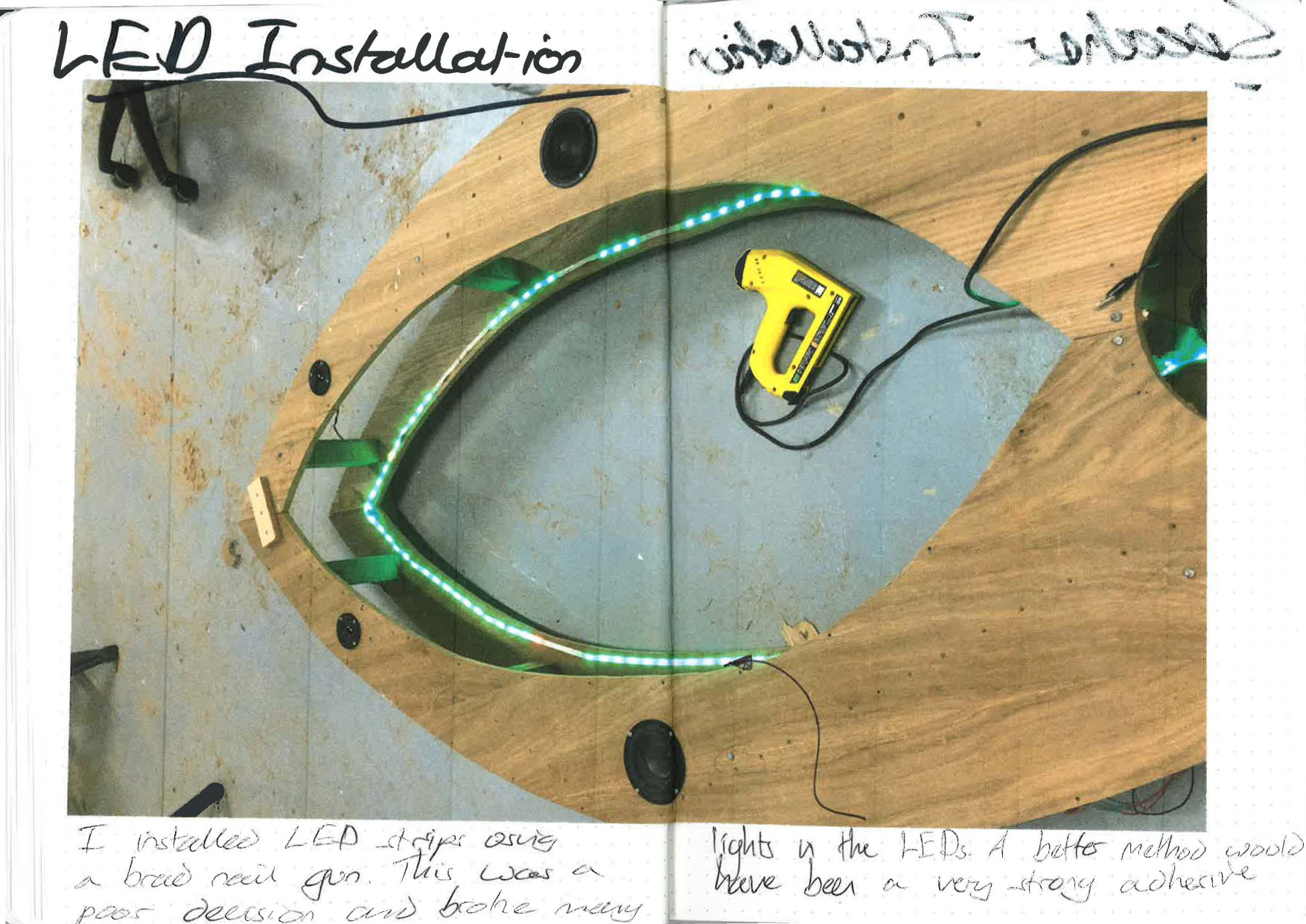

LED Implementation

Lighting was implemented using a basic LED system that could be attached using adhesive to the inside of both sides of the frame.

Power Unit Installation

With all these electronics a power unit was necessary to transform the right voltages necessary for use in audio electronics.

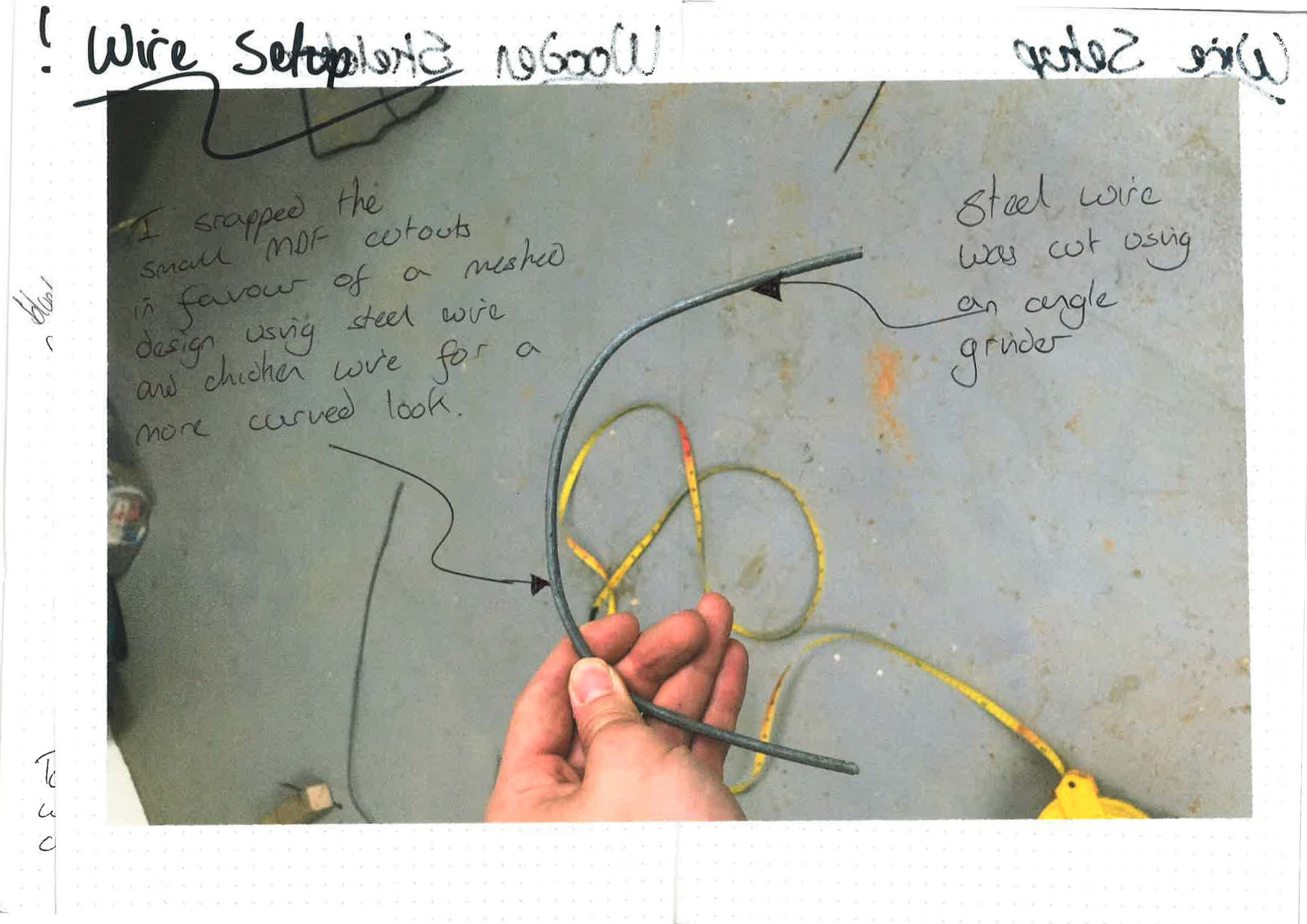

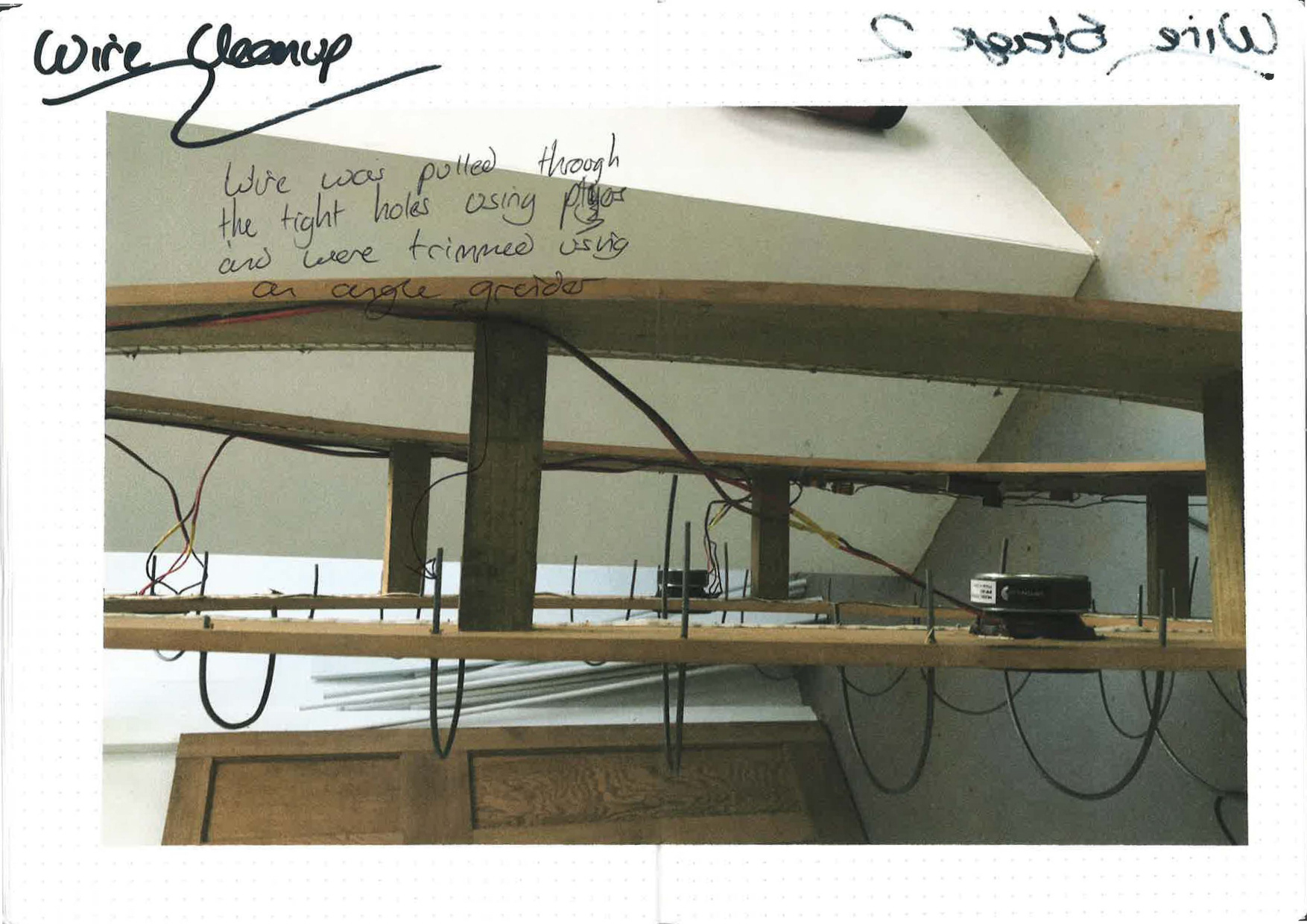

Mesh Design

To create the mesh, an experimental method was used. I bent 1/4 inch wire using some pliers into increasingly large semi-circles, before driving them through the frame and gluing them in place.

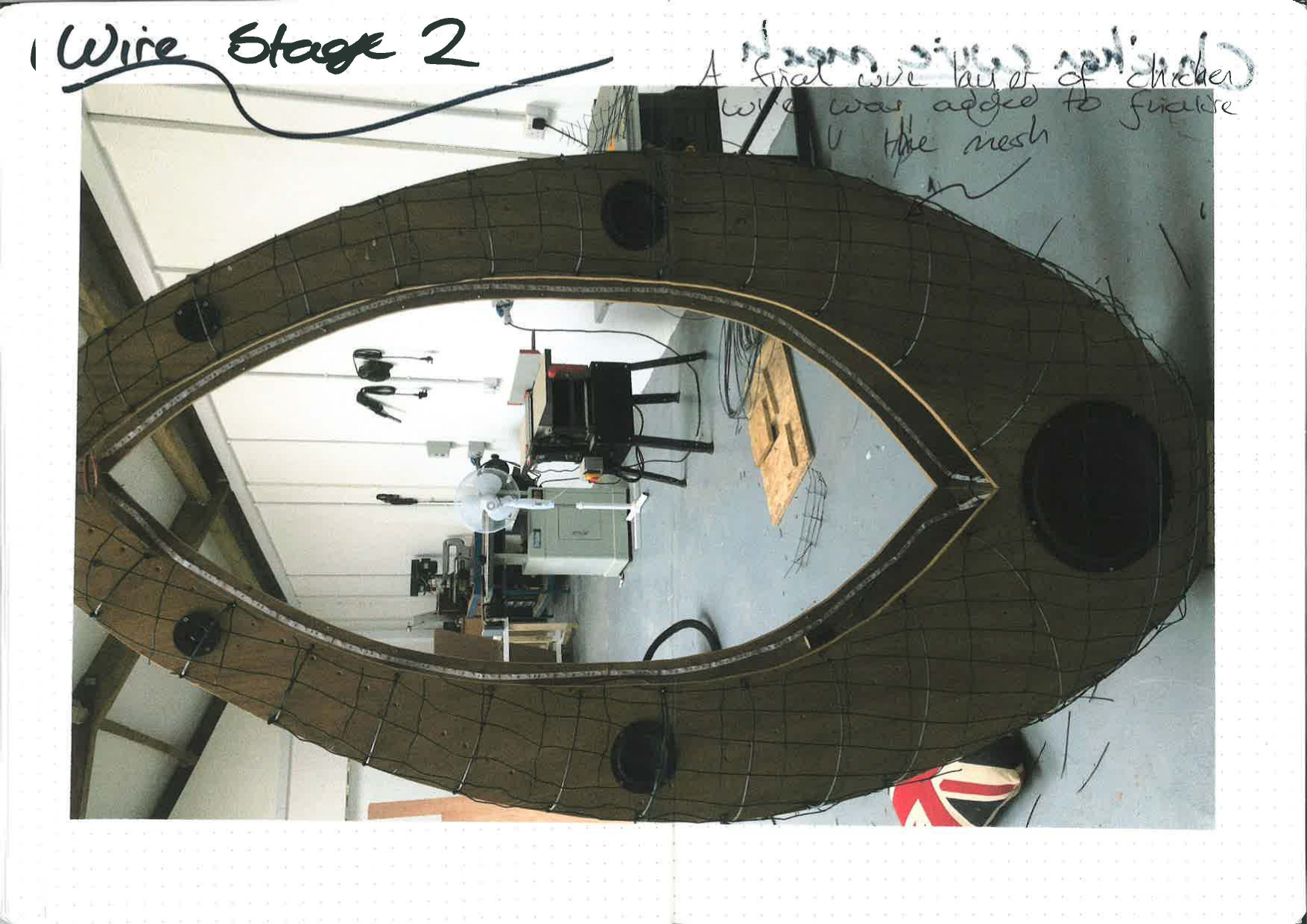

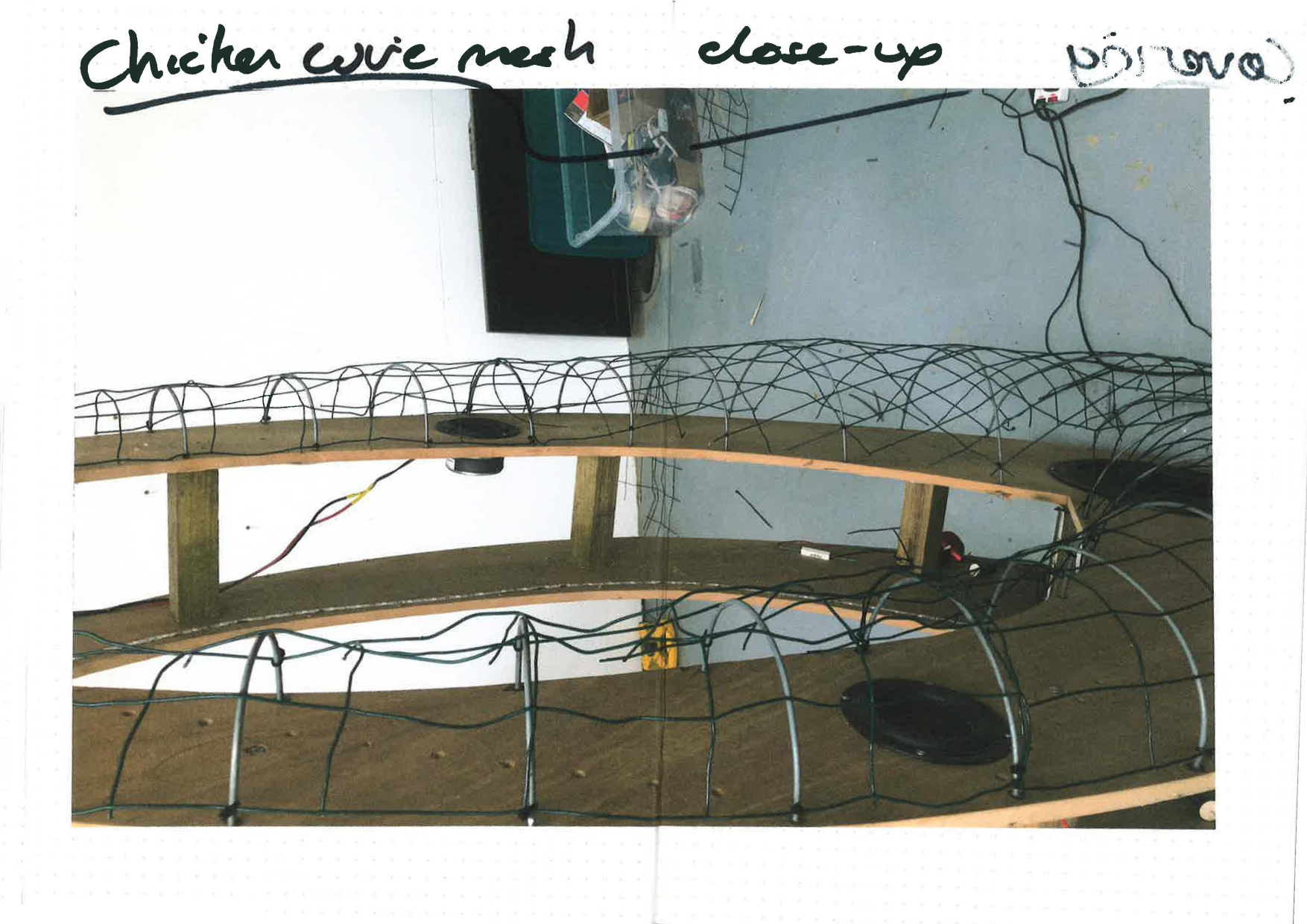

Mesh Reinforcement

To make the mesh seem as seamless as possible, chicken wire was laid on top of the initial mesh supports, allowing the fabric to be distributed more evenly.

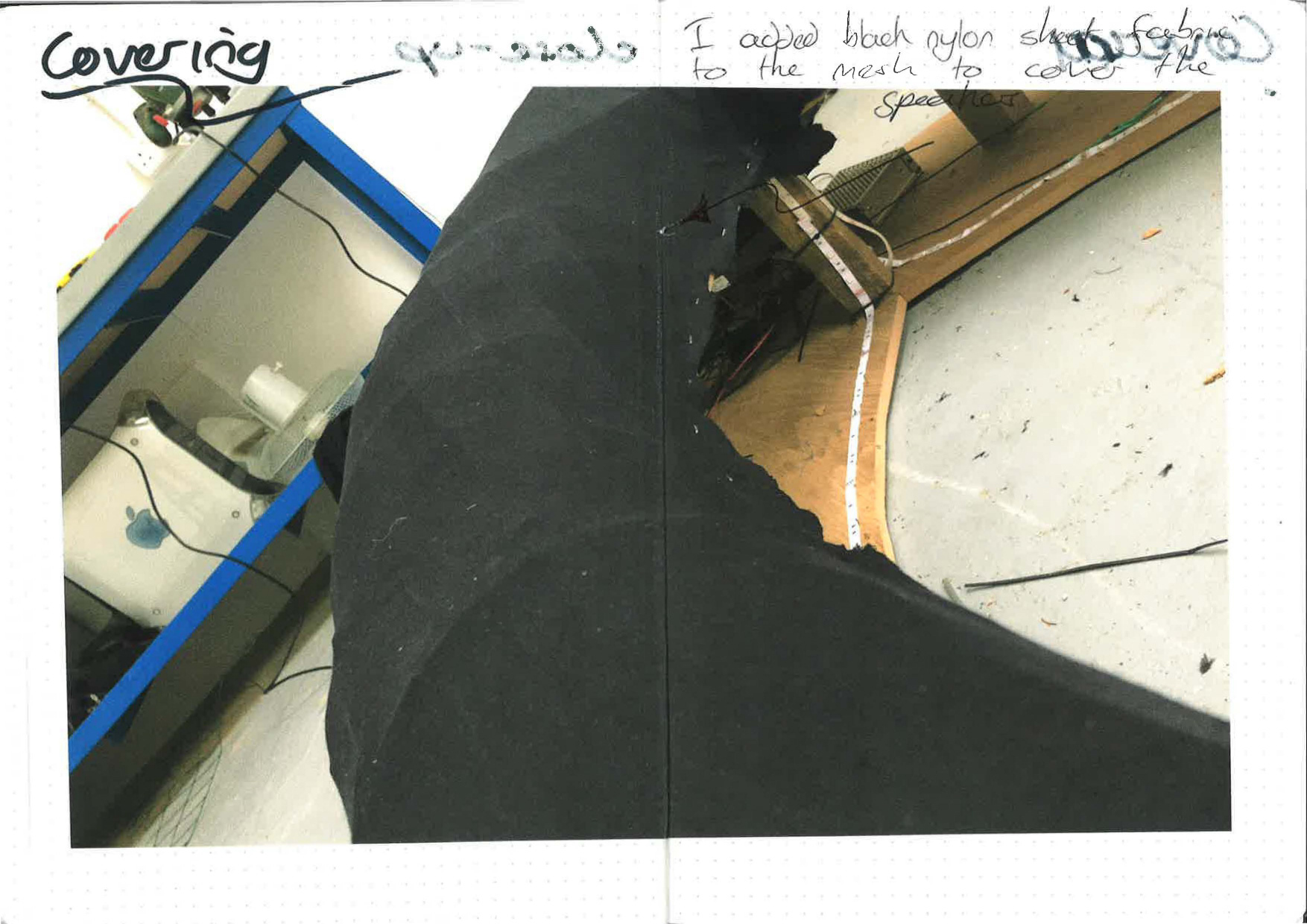

Mesh Covering

Using the mesh wire as a foundation, black cloth fabric was used to mimic the common materials used in speaker design. This was sewn and stapled into place.

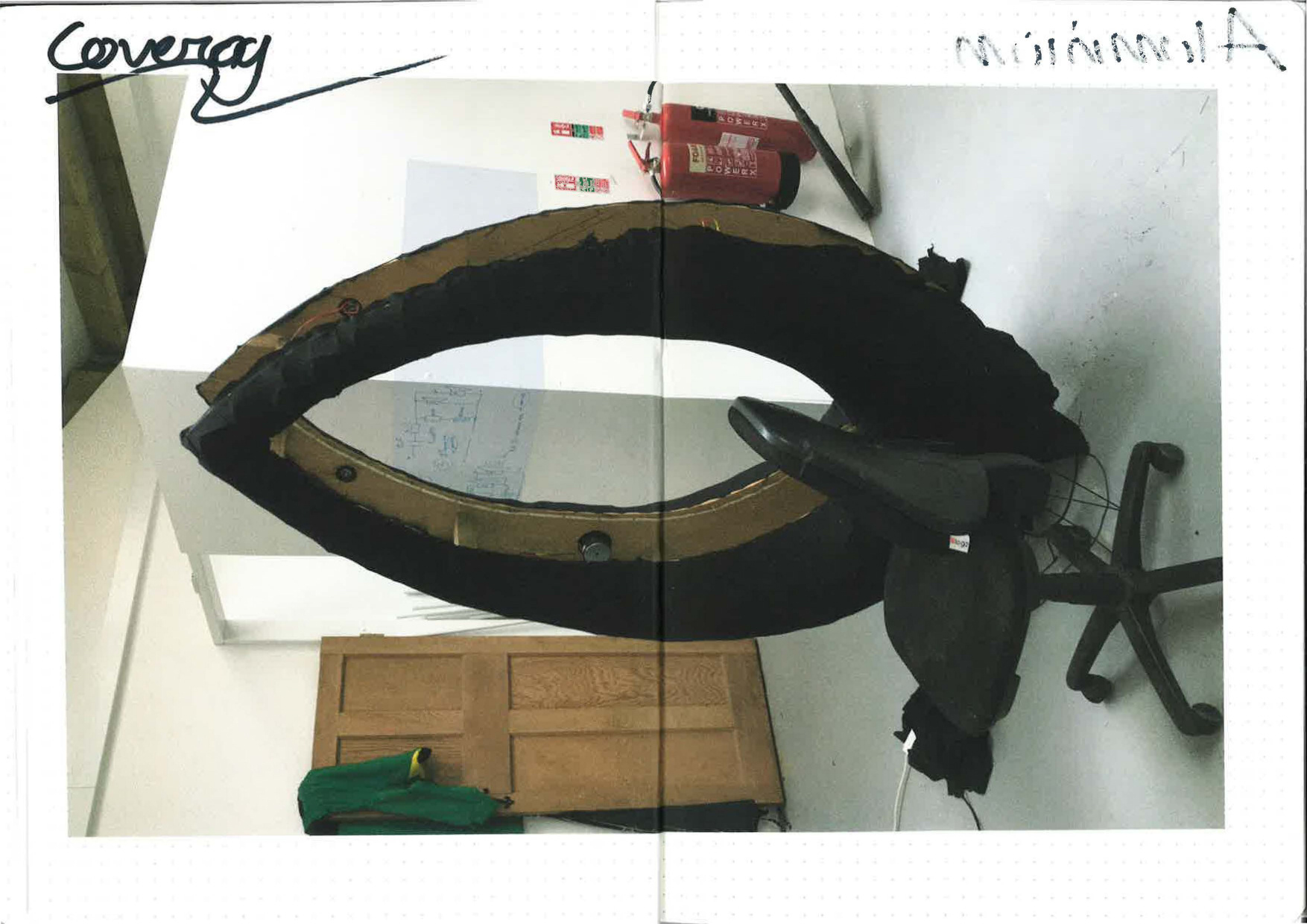

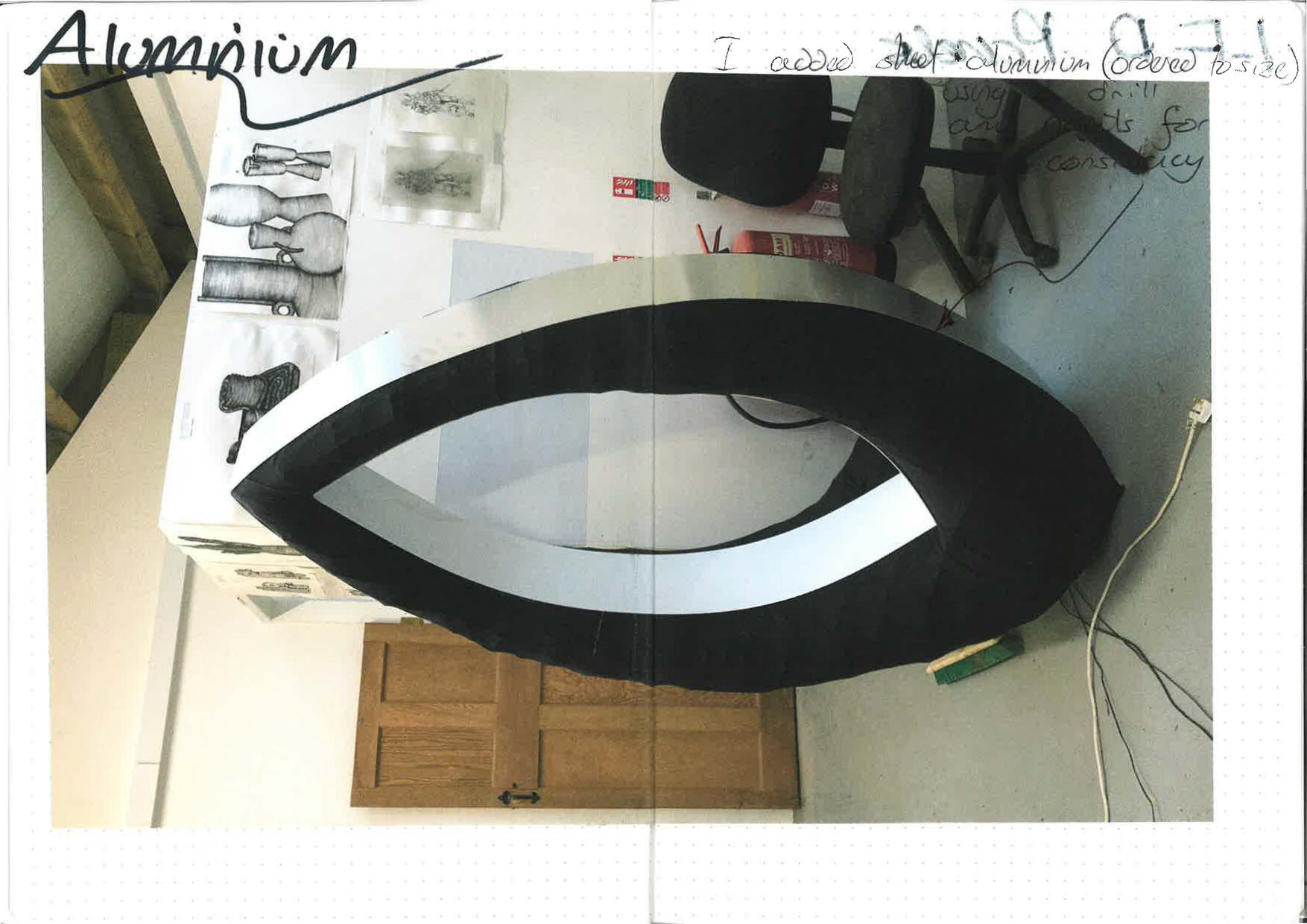

Aluminum and LED Covering

To finish up the design, aluminum and frosted acrylic were attached to the sides of the frame, typing up the design.

LED Testing

The LED system was tested and validated with results being very satisfactory, the project had worked!

Recording of Progress

Since this part of the project was self-proposed, I decided to create a documentation off my own back in the form of a notebook, some pages of which I have collected here.

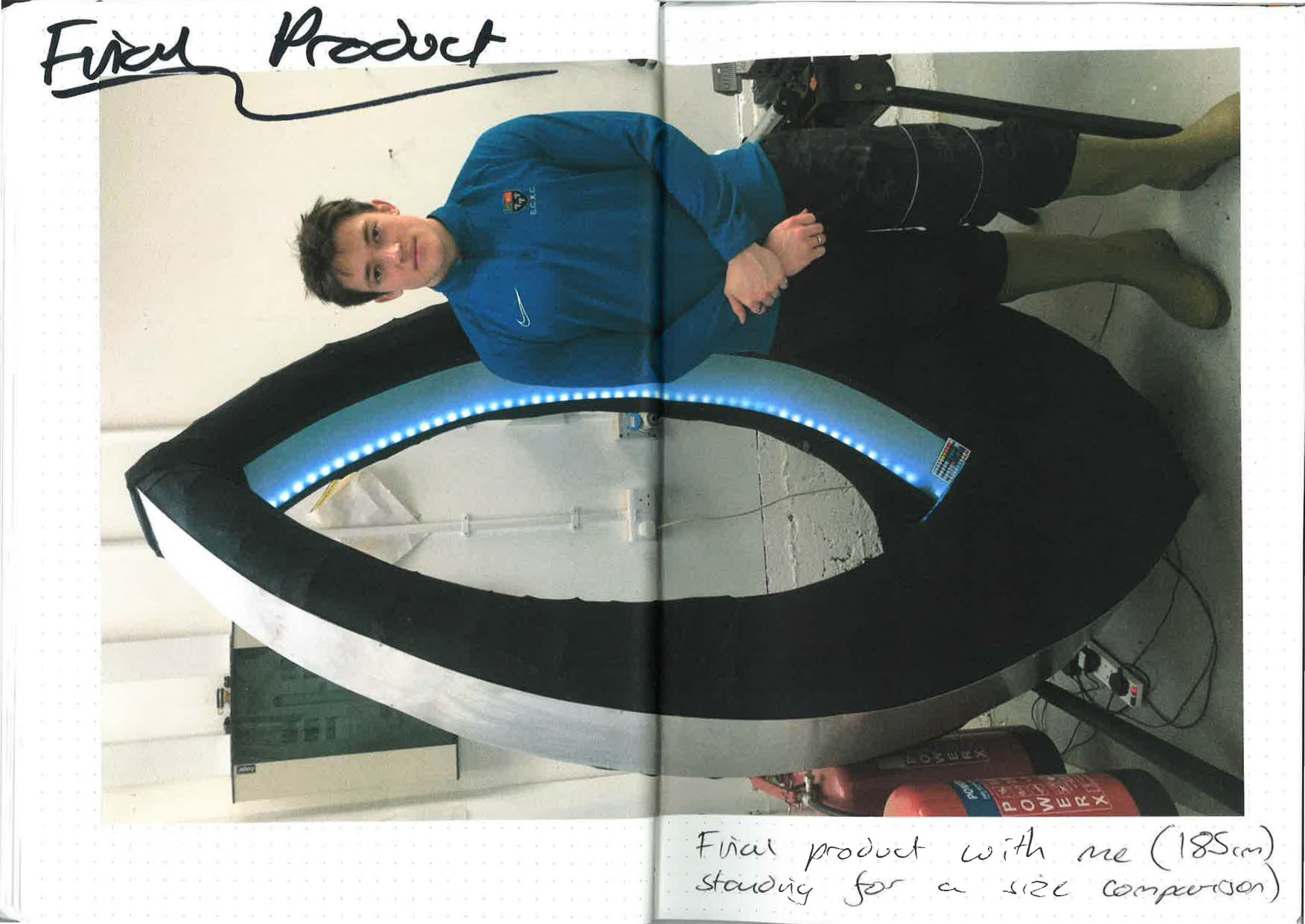

Final Product

The final design was completed, and the accompanying documentation was finished.

Awards

Winner of the Bang and Olufsen Industrial Design Competition.